Introduction to LHB Coaches

(Linke Hoffmann Busch GMBH – German)

Indian railways have been manufacturing passenger coaches of “Schlirien” design for more than 50 years. Although continuous efforts were being put to upgrade these coaches, due to constraints/limitations in the design, we could not cope up with quality and speed of the Railway transport in the developed countries.

It was felt to imbibe technology in-use, in the developed countries so as to affect a quantum jump in quality and speed of Railway coaches.

“M/s Alstom and Linke Holfmann Busch (LHB)” are one of the leading manufacturers in transport sector having presence in most of the European countries. Coaches manufactured by them are running in many countries across the world.

LHB coach body is designed and manufactured by leading German company Linke Holfmann Busch GMBH and Bogies for these coaches is designed and made by M/s FIAT, Switzerland which is now a part of Alstom group. Indian Railways entered into a TOT agreement with M/s. Alstom Germany for manufacture of LHB type of Coaches. Accordingly, their inception and mass production in Railways started in 2002 and population is growing day by day.

3.2 SALIENT FEATURES OF LHB COACHES

These coaches are longer by 1.7 meters than the ICF coaches and hence more number of passengers can be accommodated in a given coach. As the length of the coach is longer the number of coaches required to form a formation is reduced and hence overall cost of maintenance becomes less.

These coaches are fitted with Axle Mounted Disc brakes to have an effective brake power to stop the train within the short braking distance. As the brake forces are acting on the Discs which are mounted on the Axles, the wear on the wheel tread caused due to brake application on tread is eliminated and hence the life of the wheels are considerably increased.

These coaches are fitted with Wheel slide protection device to prevent the wheel from getting skid. Due to various reasons it is possible for any one of the wheel to have lesser speed when compared to the other three wheels and in such a case it releases the air from the brake cylinder of the affected wheel automatically to prevent the wheels from getting skid.

These coaches are fitted with Brake accelerator in the Brake pipe to bring BP pressure to zero during emergency brake application. The brake accelerator connects the Brake pipe with exhaust during emergency application to facilitate faster exhaust of air from the brake pipe.

These coaches are provided with FIAT bogies, which are designed to run at a speed of 160 KMPH. The wheelbase of Bogie is 2560 mm.

These coaches are fitted with earthing device to prevent damages to the Roller bearings. These coaches are fitted with roof mounted AC package units.

These coaches are fitted with Controlled discharge Toilet system designed to discharge the human waste when the speed 125 reaches above 30 KMPH. The objective of this toilet system is to keep the station premises clean and hygienic.

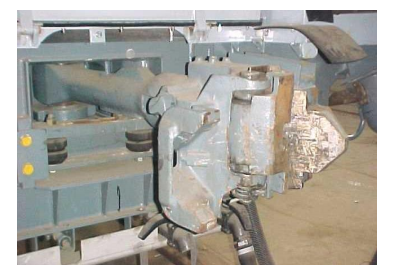

These are fitted with tight lock AAR centre buffer coupler with anti-climbing feature to prevent the climbing of one coach over another in case of accidents.

The following equipments are operated by Microprocessor controlled system

- Wheel slide protection device.

- Controlled discharge toilet system.

- Water pumping device.

- Roof mounted AC package units

The riding index of LHB coach is 2.75 when compared to 3.25 in case of ICF Coaches.

Up-graded design for passenger safety/comfort like; Ergonomically designed seats as per Indian anthropometrics data, 126 Large windows with good visibility, Luggage racks with in-built reading lamps, Insulation against noise, No visible screws in the interior. Use of fire retardant materials, Hand – safe feature in all automatic sliding doors, Anti – skid PVC flooring, UIC vestibules and auto - closing vestibule door.

Functionally designed pantry area is easily accessible AC unit controls. The passenger emergency alarms signal devices (emergency alarm pull box) are provided inside passenger compartment. This is to avoid operation of PEASD by unauthorized persons from outside. There is no mechanical linkage like a chain and this handle directly operates the PEA valve for venting the brake pipe pressure.