FREIGHT TRAIN EXAMINATION

Introduction: The efficient working of freight stock is closely linked to the standard of yard maintenance. Several factors are responsible for good and quality examination/repairs in the yard. The method of examination is described as under.

New Pattern of Freight Train Examination: It is based on the Revised JPO issued by Railway board letter No. 94/M(N)/951/57 Vol-2 dated 25.10.04,letter NO-2005/M(N)/951/13 Dated 07.04.05 and even no dated 25.04.2006 and 5.11.07.

Following are the main feature of new pattern examination of freights trains.

i. Word CRT has been deleted as the stock has been phased out.

ii. The freight train can only be subjected to examine for intensive End to End, Premium End to End and Close Circuit rakes.

iii. The practice of safe to run examination of freight trains per se may be discontinued.

iv. En route rolling-in-Examination freight trains may be discontinued. How ever rolling in examination as part of intensive examination will continue.

v. Post loading examination by TXR Staff may be discontinued for all type of stock (except loading of steel consignment). This check is to be carried out by Guard and Driver as per standard proforma issued by Railway Board. The post loading check must be carried out by TXR Staff and securing of steel bundles with lashing chains may be ensured.

vi. After Tippling the rake will be offered for post Tippling examination, in case less than three rakes are day, the check may be carried out by guard and driver as per standard proforma issued by railway board. In cases 3 or more trains are being tippling, post tippling check will be done by Skelton TXR staff. After tippling the rakes should be subjected post tippling check either by TXR Staff or by GUARD &Driver in case of non provision of TXR Staff in siding.

vii. It should be ensured that unexamined lead (after unloading before next TXR Point)of freight trains running end to end pattern or invalid BPC in case of premier & cc rakes does not exceed 400 kilometer .

viii. Since multiple loading and unloading are permitted in CC & Premium Rakes .movement of CC rakes &premium rakes will be monitored through FOIS by Traffic Department with C & W control.

ix. In case of mechanized loading an unloading (i.e. BOXN wagon examination by TXR will be desirable. x. In case of clearance of stable load instruction contained in Board letter No. 2000/safety (A&R) /19/35/ dated 31.7.01 should be followed.

xi. The CC rakes shall be offered for PME in empty condition at the cc base depot where the cc base depot where the cc rake was originally formed.

xii. ROH and POH wagons from CC rake will be marked and detach at base Depot.

xiii. The rake integrity of CC rake as listed in the BPC should be maintained .However up to 4 wagon (10 FWU) may be replaced by good examined wagons in the entire Run between the two PME.(05 BLC or one mark in case of BLC rakes allowed for attended or replaced).

Premium Rakes: This new type of examination for air brake stock (i.e. BOXN, BOXNHS, BCN, BCNHS, and BOBRN etc) introduced in Indian railway w.e.f. April 06 as per instructions issued by railway board.

The salient features of such types of examination are under:

i. Premium rake will be form out of air brake stock (i.e. BOXN, BOXNHS, BCN, BCNHS & BOBRN etc.)only.

ii. Such rakes will be given intensive examination in empty condition at nominated examination yard only.

iii. Premium examination point must be upgraded to “A” category yard on top priority. iv. Stipulation to form rake out of Off POH /ROH wagons as in case of CC rakes are not applied in case of premium rakes.

v. Similar types of wagon are taken to form premium rakes, mixed wagons not allowed for such rake. vi. The rakes will be turned out with minimum 95% brake power and BPC will be issued on Green Book only.

vii. The validity of BPC to be issued for 12 days including date of issue. However grace period of 3 days is given when rake is loaded condition and on 15 days rake must be unloaded and must be offered for C &W examination.

viii. The rake is handed over to Operating Department for multiple loading and unloading within 12 days.

ix. After each loading and unloading , the rake must be offered for Guard and Driver check before commencement of journey as per proforma issued by Railway Board and observation will be recorded on the relevant column of the BPC.

x. Movement f premium rakes will be monitored through FOIS by Traffic Department with Mechanical Department. xi. If the rakes stabled in yard more than 24 hours, the rakes must be offered for C&W examination otherwise BPC will be treated as invalid.

xii. Man hours are decided as 75 for Premium End to End (PEE) examination.

xiii. The integrity of rake will be maintained. How ever 4(10 FWS) wagons may be replaced by examined wagons en route.

Advantage of Premium Rake: Following are the advantage of introducing premium rake examination:

i. Wagon turn round is reduced and loading cycle is increased by 3 times.

ii. Rakes are available for maximum to Traffic Department.

iii. During the year 2007-08 a profit of 2000 crore is made to Railway by increasing 40 million ton loading on premium rake pattern.

iv. Overall average yard detention of Indian Railway is reduced from 15 hrs to 11.15 hrs.

v. Due to introduction of premium rakes the availability of rake for end to end examination over IR decreased from 400 rakes per day to 150 rakes per day due to this over all expenditure on examination reduced.

Disadvantage of Premium Rake: Since the examination of premium rake are being also attended in yard which is yet upgraded to ‘A’ category, Following are the disadvantages:-

i. Man hours for Examination of premium rakes are not specified and are being examined on end to end pattern.

ii. Reject able Items for attending examination and repair of such rake are also not specified.

iii. The rake is permitted for multiple loading and unloading on the basis of GDR check. It is experienced in N. C. RAILAY that GDR check is not effective and derailment of 3 premium rakes during 2006-07 as 2007-08 were occurred due to lack of GDR check which is not safe practice and not safe to rolling stock.

iv. Grace period of 3 days is permitted when rakes are in loaded condition (i.e. in rare cases) and must be reached to unloading point within 15 days and on 15th days rake must be offered for C&W examination .

But it is experienced in NC Railway that Traffic Department is taking advantage of grace period, the premium rakes are received after loading on 12thg day from the issue of BPC and thus rakes are running on invalid BPC. Such information is being sent to Railway Board in PCDO and operating department is requested to minimize such practice to safe running of rolling stock.

Close Circuit Rakes: CC rake are being formed in term of Railway Board’s letter No.94/M(N)/951/57 Vol- II dated 25.10.2004 and letter No. 87/M(N)/951/31 dated 22.08.1989. and 404 time to time instruction issued by Railway Board. Following are the main feature of CC rakes:-

i. CC rakes will run on predefined path and under completion of day / km mention on BPC the rake should be examined at nominated base depot only.

ii. Off POH/ROH wagon should be preferred during formation of CC rakes.

iii. Examination should be conducted in day light only (morning to sun set).

iv. The examination should be conducted on nominated line by CRSE & CFTM of the Railway.

v. All reject able items must be attended during examination of such rake.

vi. The air brake wagons of same types of stocks are formed in CC rake .Mixed wagon can not be allowed.

vii. For examination of CC rake, 100 man hrs is to be taken.

viii. After examination BPC with 100 % brake power is issued on prescribed yellow color certificate. ix. The examination of CC rakes is carried out where the minimum infrastructure facility for examination as standardized by CAMTECH is available.

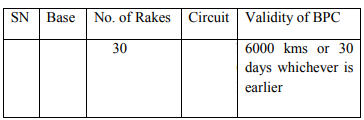

x. There are 3 types of CC rakes be examined and validity of BPC being issued over Indian railway.

4500 kms/20 days whichever is earlier (examined at “A” ,”B” and “C” Cat. yard)

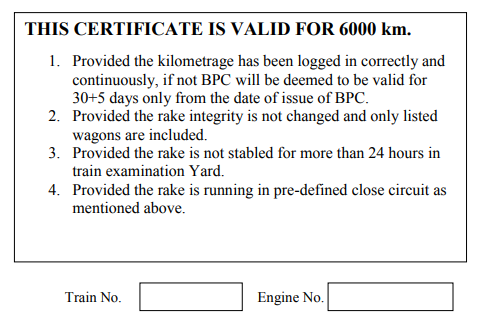

6000kms /30 days whichever is earlier (examined in “A” cat. yard)

7500 kms/35 days whichever is the earliest (being examined at Special “A” cat. yard)

xi. The rakes are handed over to Traffic Department for multiple loading/unloading within the validity of BPC and GDR check.

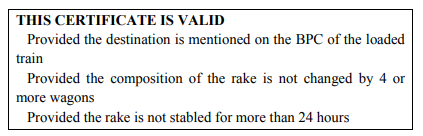

xii. Listed wagons on BPC are allowed to run .En route if detachment or attachment by 4 or more wagons (10FWU) is done without examination by TXR, BPC should be treated as invalid (In case of BLC 5 wagons/ one unit)

xiii. Movement of CC rakes will be monitored through FOIS by Traffic Department with Mechanical Department.

xiv. If the rake is instable in yard more than 24 hrs in yard, the rake must be offered C&W examination and if not, BPC should be treated as invalid.

xv. The km runs must be endorsed by Driver and Guard on BPC in relevant column.

Further, zonal Railways shall maintain detailed record w.r.t. en route detachments. Brake power and detachment during examination of these rakes and give monthly feed back to board on their performance.

Railway must ensure that infrastructural facilities at all the above points are upgraded to ‘A’ category.

11.1 POST LOADING AND POST TIPPLING EXAMINATION:

Vide Rly Bd’s letter no. 2005/M(N)/951/13 dated 08.02.2006.Post Loading examination by TXR staff was discontinued. Post loading check by Guard and Driver was introduced. In the para (iv) of Rly Bd’s above letter dated 08.02.06. It was stipulated that:

After tippling the rake will be subjected to post tippling examination. In the case less than 3 rakes are being tippled per day, the check may be carried out by Guard & Driver as per proforma enclosed. In case 3 or more trains are being tippled, post tippling check will be done by skilled TXR staff.

The same has been reviewed vide Rly Bd’s letter No. 98/ M (N)/951/12/pt.1 dated 17.05.07, relevant paras are reproduced as follows:

1. Board has reviewed the subject matter and has decided to revise the instructions contained in para (iv) of aforesaid letter dated 08.02.06 on post tippling checks on freight trains as under:

a) After tippling rake should be subjected to post – tippling checks either by TXR staff or by Guards and Drivers in case of non provision of TXR staff in the siding.

b) As local condition may vary from siding to siding, based on recommendations of CME & COM, GMs may decide whether the post tippling check on a particular point will be entrusted to TXR staff or Guard and Driver. While deciding the matter one way or other, the following may be kept in mind:

- Recovery of necessary charges from the owner of such sidings in case any defects damages are noticed.

- Post tippling check by Guards and Drivers should be done as per format enclosed with the above mentioned letter of Railway Board.

2. Rules regarding starting of trains from non-TXR points after examination by Guard and Drivers should be strictly en forced.

3. All other provisions of Board’s letter no.2005/ M(N)/ 951/13 dated 08.02.2006. It is to be followed.

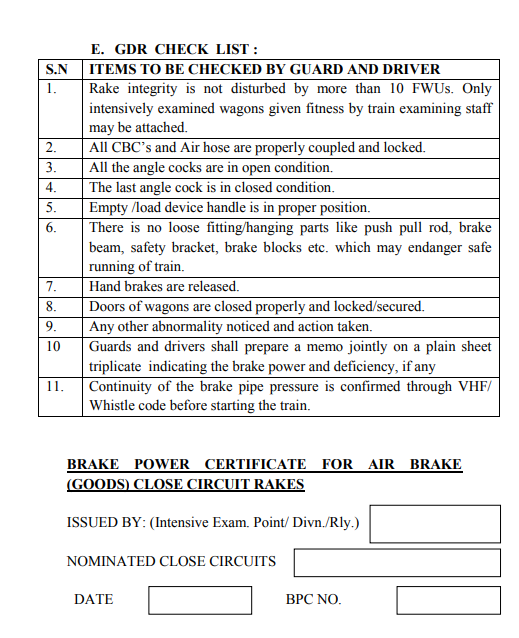

GDR CHECK: GDR check has been defined as , required to be done only for rakes , which are to be offered to TXR examination, where due after completion of loading and unloading cycle and are required to move another 250-300 kms ( now 400 kms stretch) before hitting the TXR points. The GDR check by guard and loco pilot should invariably ensure the following:-

1) Adequacy of Air pressure/vacuum pressure in motive power and brake van.

2) Ensure Air pressure / vacuum continuity from loco to last vehicle.

3) Success of brake feel test.

4) Adequacy of brake power by counting operative/ non – operative pistons.

5) Shall ensure by visual examination that there are no loose fitting in the under gear including brake blocks, safety brackets , track area, brake gear pins etc. which may danger the safe running of train. This examination shall be one by walking along the length of the train by loco pilot on one side and by Guard on other side.

6) Guard and loco pilot shall jointly prepare a memo in triplicate indicating the brake power deficiency, if any .They shall append their signature on the same and both of them shall retain a copy of the same and third copy shall be handed over to station master on duty.

7) In case of premium end to end rakes the observation by the guard and loco pilot will be recorded under the relevant para of the BPC.

The GDR check should not lead to a false sense of adequacy of brake power in the psyche of the loco pilot. So apart from adequacy of air pressure per vacuum in the locomotive and the last vehicle, the loco pilot should have the confidence on the adequacy of the brake power only after conducting the brake feel test and this aspects of sufficiency of brake power of the train should not be diluted by other visual examination by Guard and Loco Pilot.

Since premium rake s allowed for multiple loading and unloading up to 12 days based on the GDR check, there is an urgent need to bring improvement in quality of GDR checks by imparting suitable training to all goods Drivers and Guards. Some of the areas that need to be specifically covered in such training are as follows:

i) Significance of post loading and post tippling examination.

ii) Items to be checked: critical assemblies and components: procedure for checking.

iii) Type of BPC s: validity of BPC: action to be taken in the case of invalid BPC.

iv) Type of tipplers / pay loaders: nature of the damage caused to the freight stock during loading per tippling operation.

v) How to check brake power of air and vacuum brake train? How to check continuity of air pressure/ vacuum in trains?

vi) How to check condition of couplers, hoses and other under gear components .

vii) Types of the angle cocks: open / close position of different type of the Angle cocks.

viii) Empty / load device: principle of working /correct position of empty / load device handle.

ix) Types of the bogies suspension arrangement, brake gear components, common defect of spring, brake pull load, brake beam, safety bracket, brake block etc. And action to be taken in each defect.

x) Type of hand brake, procedure of release/application of various types of hand brakes / defect of hand brake.

xi) Type of doors and their locking in various type of wagons, door opening mechanism of BOBRN wagons.

xii) Action to be taken for various defect in freight stocks / train.

Post Loading/ Post Tippling Checks by the Guard and the Driver

(Signature of Driver) (Signature of Guard)

Driver’s Name………………..

Guard’s Name……………….. '

(This memo should be prepared in three copies, one copy to be kept with Driver , one with the Guard and one will be given by the Guard to the Station Master / Yard Master.)

Examination of Container Trains (In each case of invalid BPC):

(Ref: Railway Board’s letter No. 2007/M (N)/ 951/67 Dated 19/20. 11.2008);

i) Para 2.9(a)- In empty Condition (container off loaded from wagons):

Rake shall be offered at the nearest TXR point for intensive examination, where after examination its BPC will be revalidated for a period of 7 days, with endorsement on BPC by TXR that rake is safe to run up to its base depot. During this period of 7 days, one loading/ unloading shall be permitted in the direction of CC base depot. The revalidation of BPC in above manner is permitted only once and rake shall be back to its CC base depot within 6 days period. Else the rake shall lose its CC character and will become normal end-to-end rake Reconversion of such end-to-end rakes to CC shall be permitted only after personal approval of CME & COM of the concerned Zonal Railway.

ii) Para 2.9(b)- In loaded Condition (container loaded on the wagons):

Rake shall be offered at the nearest TXR 412 point for safe to run examination and endorsement on BPC by TXR that train is safe to run up to its destination. After unloading of consignment at destination, such potential unsafe rake shall be offered at the nearest TXR point for safe to run examination and endorsement by TXR on BPC that the train is safe to run in unloaded condition up to its CC base depot examination with containers loaded on wagon, shall be done only in case of extreme urgency with prior approval of CME & COM of the concern Zonal Railway.

iii) Para 2.10 of the same Railway Board’s letter dated 19/20.11.2008:

Container rakes detained for more than 24 hours at TXR point, shall be subjected to safe to run examination and endorsement on BPC by TXR that rake is safe to run for the remaining validity period of BPC.

JPO for Close Circuit Pattern of Examination, Maintenance and Operation of BTPN Wagons (Ref: EDME/ Frt./Railway Board’s Letter No.-2008/M(N)/951/13 CC Rakes dated 05.02.2010)

i) After successful trial for one month Close Circuit Examination of BTPN wagons shall be taken up at BAAD Depot in Agra Division on trial basis for one year as detailed below:

ii) CC examinations will be done only on the examination lines in the Yard having proper facilities of material handling, pucca pathway, welding, lighting etc. the CC examination will be done on the lines where there is no OHE.

iii) If there is no CC examination line without OHE, CC examination and maintenance of under gear parts of wagons should be carried out in the CC examination Yard and maintenance of barrel portion of the wagon (i.e. barrel mounting and valves) may be done in gantry before loading of the product.

iv) The existing rakes (ordinary/ non CC/ Premium) shall be thoroughly examined before the rake is declared CC by a supervisor not below the rank of SSE/C&W.

v) The rake shall be offered for examination in day time only, till the lighting facility is developed.

vi) Due to acute position of staff at BAAD Sr. DME/ C&W/ AGC may move 8 staff from BAAD sick line to yard for three days a week. On these days , CC examination may be carried out @ one rake per day . This will be done till additional staff is posted at BAAD depot.

vii) All wagons released from ROH shall be utilized for making CC rakes and Off ROH wagons waiting for formation of CC rakes shall not be considered under ineffective.

viii) During CC examination, proper attention to the safety fitting ,pipes valves etc shall be given and their maintenance records will be maintained separately.

ix) Monitoring of CC rakes shall be done through FOIS and also by Sr.DME(C & W) and Sr.DOM of AGC division jointly.

x) Proper computerized record keeping and documentation at CC base depot BAAD to be ensured to be monitor condition of CC rake.

xi) The BPC will incorporate the name of CC depot as BAAD depot and will be valid over NCR,NE,WR,NR&WCR with a validity of 6000 kms or 30 days whichever is earlier.

xii) Rake operating on zonal railways not mention on the BPC will loss their CC character and will be treated as per instruction prevailing for normal end to end rake.

xiii) All rakes will be returned to BAAD depot , nominated CC base report as per validity of BPC.

xiv) After each loading /unloading, the rake will be examined by Guard and Driver before commencement of journey and observation will be recorded under relevant column of the BPC.

xv) Rake integrity as listed in the BPC should be maintained, however up to 4 wagons may be replaced by duly examined wagons in the entire running between two PMEs.

xvi) ROH/POH wagons from CC rake will be marked end detached at base depots only.

xvii) In case CC rake is not made available for examination at base depot and offered for examination at some other depot. It will become non CC rake and it will follow normal intensive examination pattern.

xviii)Railway shall ensure that other requirements as stipulated by RDSO from time to time & IRCA for carrying and handling of hazardous material in the tank wagon shall be met.

xix) Besides special conditions mention here in above , with respect to maintenance and operation of this special CC rakes, all other general instructions issued by railway board from time to time, regularly maintenance of 6000 kms CC rake shall be observed.

xx) After completion of 1 year of trail period, division should submit performance report with detail of detachment (with reasons), poor brake power cases and detachment during examination etc. for review.

Items to Be Examined/Checked During Premium/Cc Rake Examining In Yard (Brief):

Rolling In examination must be done before block of rake to detect Hot Box, flat tyre and other unusual.

1. Complete inspection of running gears, break gears & spring gears including tapping and gauging of wheels. The wheel dia should be within limit.

2. Ensure fitness of all safety fittings, straps & safety loops, safety brackets etc.

3. Replacement of cast iron & composite brake blocks. Brake blocks should be replaced on reaching condemning thickness. After fitment of brake block and key on brake head fitment of split pin should be ensured. The limit of brake block thickness is as under :

4. Correct functioning and positioning of empty load device.

5. Checking and proper securing of doors of the wagons.

6. Look for abnormal and/or unequal buffer height/CBC height, wear plates, knuckle, etc to the extent it is possible to detect by visual examination. Incase of doubt , the buffer height / CBC height should be measured and maintained as given below :

7. The Bogies, complete side frames and bolsters to be visually examined for cracks and missing parts. Bolster springs , Snubbers, spigots, center pivots fastening, roller side bearer in case of CASNUB 22 bogie to be checked for defects , if any. Following nominal clearances may also be observed;

8. Hand brake Wheel should be checked for their proper working in ON & OFF position.

9. Visual examination of under frame members, body, door mechanism, CBC wear or deficiency of parts to be marked and their operation to be checked.

10. Examination of any loose or hanging component. 11. Abnormal behavior of any vehicle indicates if unsafe working condition.

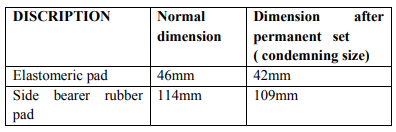

12. The condition of side bearer pads Rubber bonded metal pad (RBMP), E M Pad must be examined and it should be within limit as given below.

13. A rake of air brake wagons should be tested with rake test rig from one end of rake. Leakages through air house pipe, MU Washers, cut off angle cock to be arrested and air pressure in BP gauge should be maintained as given below:

14. During the testing following parameters are to be checked and maintained as given below:

a) “A” Dimension:

b) Piston stroke:

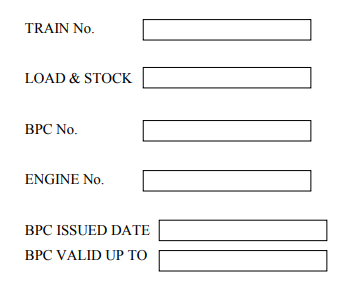

15. Brake Power Certificate (B.P.C.):

This is a certificate jointly signed by guard, driver and C&W supervisor prepared in triplicate by C&W supervisor after ensuring vehicle attached in train is fit to run and required amount of vacuum/ pressure is maintain in engine and brake van/ last vehicle. It contains train no., engine no., and loads, break up of load, brake power of the train, amount of vacuum/ pressure in engine and brake van and first and last two vehicles number respectively.

BPC to be issued on prescribed color performed as under:-

Premium rake – Green color - 95%

CC rake – Yellow color - 100%

End to End vacuum rake – Pink color - 85%

End to End air brake – Green color - 85 %

Brake Power Certificate For Air Brake (Boxn/Bcn) Primium End To End Rake

ISSUED BY: (EXAM Point/Div/Rly.) ______yard /Railway

INTSTRUCTIONS

A. GUARDS AND DRIVERS

Before starting the train , guard and driver should ensure:

(i) Continuity of air pressure from first to last vehicle of the train.

(ii) Validity of BPC, if found invalid inform the section controller immediately and take necessary instructions from carriage control.

(iii) Driver and Guard should correctly log the dates and kilometres earned.

B. STATION STAFF

They should be vigilant for averting any theft or tempering with this rake. Any incident of theft/ tampering to be 422 reported to section controller / TXR controller and entry of attention done be made in space provided.

Note: 3 days additional grace period is given for loaded trains only. Loading of train on or after 12th day will make BPC invalid.

B. TO BE FILLED AT THE ORIGINATING EXAMINATION POINT BY RAKE EXAMINING STAFF

INSTRUCTIONS

A. GUARDS AND DRIVERS:

1. Before starting the train, guard and driver should ensure:-

(i).Continuity of air pressure from first to last vehicle of the train.

(ii). Validity of BPC. If BPC is invalid, inform the control office & take necessary instructions from Carriage Controller/ Sr. DME.

2. Driver and Guard should correctly log the kilometers earned.

B. STATION STAFF:

1. They should be vigilant for averting any theft or tempering with this rake. Any incident of theft/ tempering to be reported to TXR Control and entry made in the space provided.

INSTRUCTIONS A. GUARDS AND DRIVERS

Before starting the train guards and drivers should ensure:-

(i) No driver should move the loaded train from the loading point unless the destination is clearly mentioned of the brake power certificate.

(ii) Continuity first to last vehicle of the train.

(iii)If BPC is invalid , inform the control office & take necessary instructions from C&W controller.

B. LIST OF WAGONS IN ORDER

C. ENROUTE PROBLEMS NOTICED AT STATION GIVEN

D. NOTES :

1. The incoming driver shall handover the brake power certificate to relieving driver . If he is leaving the train without relief . It shall be deposited with nominated authority who will give it to the outgoing driver.

2. The outgoing driver and guard will satisfy themselves from the listed wagon numbers that the brake power certificate pertains to their train.

( ) ( ) DRIVER’S NAME & SIGN.

GUARD’S NAME & SIGN.

( ) JE/SE (C&W) NAME & SIGN.

1. Rolling in examination including axle box feeling

2. Intensive examination and repairs:

Intensive examination and repairs:

A Inspection and repairs of running gear fittings.

B Inspection and repairs of brake gear and spring gears.

C Inspection and repairs of draw and buffing gear.

D Checking and making good the deficiency of safety fittings, safety brackets, safety loops etc.

E Replacement of brake blocks.

F Correct functioning and positioning of Empty Load Box Device.

G Checking and proper securing of doors of covered wagons.

H Checking of CBC and knuckle.

I Meticulous check of BC, DV, AR.CR and other pipe joints.

J After brakes are released, the wheel profile should be examined.

K Where a reject able defect cannot be attended on the train in the yard, wagon shall be damaged labeled for attention in the sick line.

Difference between STR and intensive examination:

Difference between CC and premium rake examination:

STEPS OF INTENSIVE EXAMINATION:

a. Rolling in examination including axle box feeling.

b. Intensive examination of originating train including repairs, detachment of damaged/sick wagons, brake testing etc.

c. Issue of Intensive Brake Power Certificate after ensuring brake continuity of the formed load.