Microprocessor Control Loco (MEP-660)

Now days, MEP-660 microprocessor is provided in diesel locomotive and such type of loco are called microprocessor control loco. New 11 series locos WDM3D and retrofitted WDG3A, WDM3A are microprocessor control locos. Their General Data as under -

Advantages of Microprocessor Control Loco

1. All Breakers and switches are similar to WDG3A except additional circuit breaker MPCB and PLPB for easy handling to LP

2. Very low intervention by the LP during faults trouble shooting activities by LP is simplified.

3. No reset of GR1, GR2 and GFOLR because sensors are provided for the same.

4. Pre and post lubrication feature is available.

5. Possibility of load stalling is very less.

6. Cold engine feature is provided.

7. No need to maintain the timings specified in load meter since MEP660 automatically reduces the excitation.

8. No need to regulate the Dynamic brake at high speed since MEP660 automatically reduces the excitation.

9. No slackness of cards on run.

10. Automatic isolation of TM at the time of short/open circuit.

11. More than one TM can be isolated.

12. Automatic reduction of transition speed in case of TM isolation.

13. Detailed audio video fault indications.

14. In case of locked axle system indicate clearly which wheel is locked. Description WDM3D WDG3A, WDM3A Retrofitted Engine Horse Power 3300 3100 Loco Horse Power 2950 2900 Maximum Speed 120kmph 105/120kmph Weight 117T 123T/112.8T Axle Load 19.5T 20.5T/18.8T Tractive effort 38.9T 37.8T/30.5T Brake System IRAB-1/CCB IRAB-1/CCB Transition 42, 52 km/h 41.5 km/h Governor WW/MCBG WW/MCBG Rectifier Alternator mounted Alternator mounted/self cooled/conventional

Changes in Microprocessor Control over convention WDG3A loco

1. All Breakers and switches are similar to WDG3A except additional circuit breaker MPCB and PLPB are providing on front panel. While engine starting both breakers should be in ON position

2. The pre-lubrication pump is provided in compressor room; it is use for pre-lubrication of engine before starting.

3. Following equipments are removed in this loco -ECP, VRP, TRP, BSR, TDR, BKR, CVR, TR, VRCLS, OVDR, LAS, TET, GR1, GR2, GFOLR, WSR1, 2, 3, Techo generator, axle generator, Excitation panel.

4. Following new equipments are provided in this loco – MEP-660 microprocessor control unit, display unit, distribution box (RDB & ADB1, 2,3,4), sensors (14current, 5voltage, 3temp, 7speed, 7pressure), TE limit switch, multi reset VCD.

5. Following Relays are provided in this loco – Out of 23 relays 13 relays are eliminated &10 relays retained. DMR, SANDER, VCDR, CMR, SLBR, SR, AGPR, EXPR MVR, AFLR. (FSR in WDM3D only)

1. DMR- Dead Man Relay. Same as conventional Loco

2. SR- Signal Relay. Same as conventional Loco.

3. MVR- Moisture Vent Relay. Or Magnet Valve relay. Same as Conventional Loco.

4. AGPR- Aux. Gen. Protection Relay. This relay is always be ON when the engine is running. The relay is OFF during cranking.

5. EXPR- Exciter protection relay. This relay is always ON when the engine is running. The relay is OFF during cranking..

6. CMR- Compressor Relay. This relay is ON when the MR pressure is more than 10 Kg./cm2 . The relay is OFF when the pressure is less than 8 Kg./cm2 .

7. VCDR- Vigilance control device relay. This relay is normally in ON position. During penalty bake application, this relay is OFF.

8. AFLR- Auto flasher Light relay. This relay is normally ON while running. During un-authorized BP reduction, this relay is OFF and flasher lights are switched ON.

9. SLBR- Self load box relay. This Relay This relay is ON when self load box test is selected from display unit.

10. SANDR-During wheel slip, after 15% power reduction, the sander relay is ON Wheel slip indication is ON to the driver. Automatic sanding is done.

11. FSR- Field shunting Relay. This relay is available in WDM3D Locos only. OFF.

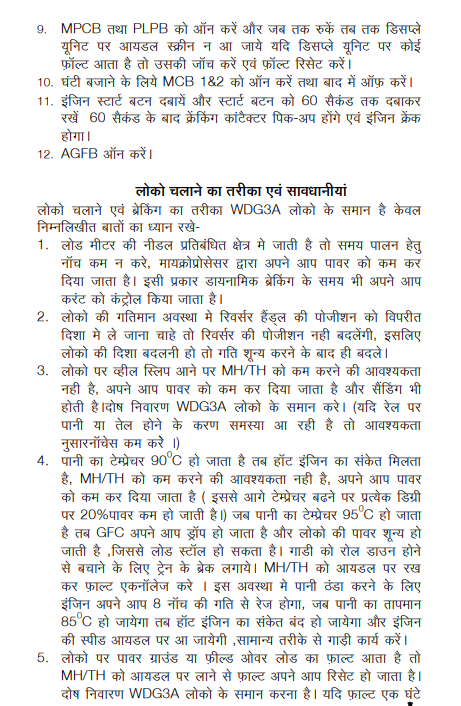

Engine starting procedure:

Before engine starting check the locomotive (safety fittings, oiling points, water level, etc.) and ensure wooden wedge & hand brake in applied condition. Then start the Diesel engine by following sequence -

1. Put ON Dome light breaker and Dome light switch.

2. Indication - Dome light will glow.

3. Close the BS in Nose room.

4. Ensure MUSD1&2 on RUN and ECS on Idle.

5. Put ON MB1& MB2 on front panel.

6. Put ON MFPB1&2 on control stand.

7. Put ON CEB, DEB, RBB on front panel.

8. Put ON FPB on front panel.

9. Put ON MCB1&2.

10. Press the alarm push button three times on front panel for ringing bell. Then put OFF MCB1&2.

11. Put ON MPCB and PLPB and wait till Idle Screen display on Display Unit

12. Press and hold the Start Button, pre-lubrication is starts. After 60 seconds cranking contactor will pick up and engine will crank. When lube oil pressure builds up to 1.3 kg/cm2, then release start button.

13. Put ON AGFB on front panel

Engine stopping procedure

1. Secure the Loco.

2. Keep MH handle on Idle and reverser handle in neutral.

3. Keep ECS on Idle position.

4. Ensure that all CB are ON.

5. Press stop button, till main crank shaft will stop.

6. “Post lubrication in progress keeps all circuit breaker ON” message will display on display screen for 5 minutes.

7. After completion of post lubrication put all circuit breakers ‘OFF’

8. Put BS in ‘OFF’

Display Unit

It is provided on front panel. When MB1, MB2, MPCB kept ON during engine starting it shows idle parameter of loco. Further it changes according to the loco pilot operation i.e. motoring display, braking display. It also shows fault messages when fault comes on loco.

Procedure of Fault Resetting

Maximum faults are reset automatically after fault recovery, some faults are recovered after keeping throttle on idle and other require acknowledging but some required to reset manually. Procedure of Manual Reset of Faults

1. Following modes will display on display unit after pressing MENU button -

1. Faults

2. Display Mode

3. Test Mode

4. Exit

2. Then pressing no.1 key on key pad following be display -

1) View active faults

2) Clear active faults

On pressing no. 2 key on key pad fault information will display, on pressing no.0 key on key pad followed by Enter button, fault will reset and next fault will display in this way clear all faults by pressing 0 and Enter key till message will appear No more fault, press menu button to exit.

Transition

Two transitions are provided in WDM3D loco, 1st transition takes place on 42 km/h from series parallel to series parallel field shunt and 2nd transition on 52 km/h from series parallel field shunt to parallel combination. In retrofitted loco only one transition takes place at 41.5kmph from series parallel to parallel combination.

Motor Cut out Switch (MCOS)

Six toggle switches are provided in front panel to isolate individual TM. For isolation of TM related toggle switch to be made off. With the help of these switches more then one TM can be isolated. Auto transitions also come even though TM isolated. Loco power and auto transition speed setting is reduced proportionate to no. of TM isolate and transition will take place on lower speed.

Vigilance control device (VCD)

VCD alerter is provided on loco to alert loco pilot in every 60 sec, if loco pilot is not alert penalty brakes were applied through VCD. VCD alerter will work if BC pressure is less than 2.0kg/cm² and MB1, MB2, MPCB, MFPB1&2, MCB1&2 should be in ON position.

VCD can be made inactive by loco pilot if one of the activities is carried out with in 60 sec -

1. Changing the position of throttle

2. Changing the position of A9

3. Application/releasing of dynamic brake

4. Change of DB level.

5. Operation of GFCO

6. Operation of sander switch

7. Pressing of horn switch

8. Changing the position of RH

9. Pressing of VCD reset button

From the above if none of activity is carried out by loco pilot with in 60 sec, VCD lamp will glow and made loco pilot alert for 08 sec. If one of the activities from above is carried out by loco pilot, VCD will reset.

If none of activity is carried out by loco pilot after VCD lamp glowing with in 8 sec then VCD buzzer will sound along with the lamp for next 8 sec and message will be display VCD time out press VCD reset on display unit. In this way 76 sec ( 60+8+8) is given to loco pilot to reset VCD, if he fails to reset, penalty brakes will applied with following changes on loco -

1. BP pressure will drop up to 2.8 kg/cm².

2. Buzzer stops sounding.

3. Engine speed comes to idle.

4. GFC contactor will drop and power contactor will also drop on bring throttle on idle and

5. Message will display VCD applied penalty brakes, press reset button to reset penalty brake.

6. VCD counter on display unit increase by one.

Procedure of Resetting VCD (Penalty Brake)

1. Keep throttle handle on idle

2. Loco should be stand still

3. Wait till VCD lamp is extinguished.

4. Press VCD reset button

Note

1. MCB1&2 to be kept off before starting the engine otherwise VCD will operate.

2. On hault BC pressure should be more than 2.0 kg/cm² to inactive the VCD in standing position of loco.

3. In trailing loco of multiple unit MCB1&2 should be kept in ON position otherwise VCD will operate but penalty brake will not come and throttle will not respond in trailing loco

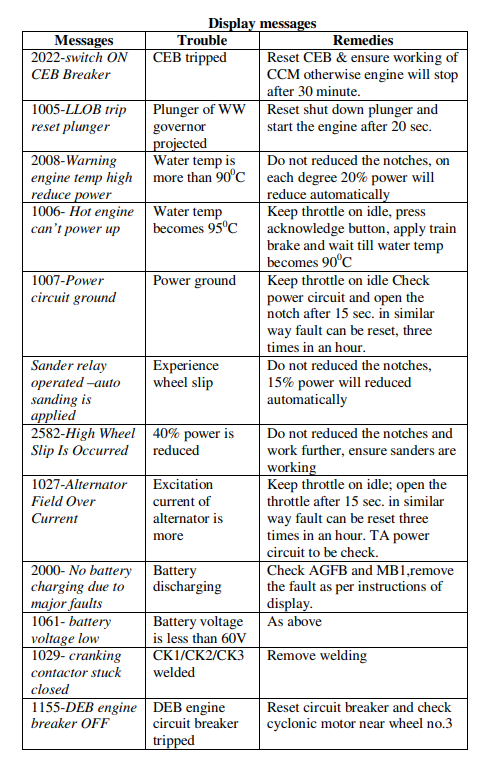

Display messages

Power Ground :-

TANGI detected power circuit is grounded. Massage on Display Unit

“1007 - Power Circuit Ground. Restrictions: Motoring Prohibited. Dynamic Brake Prohibited. Engine IDLE” With continuous alarm bell till throttle is brought to IDLE.

Power is cut off. Engine RPM is brought to IDLE. Power contactors and GF are dropped out.

Action taken by loco pilot-

Bring the throttle to IDLE and wait for 15 Sec. The fault is cleared automatically. Perform the checks as per the conventional WDG3a loco.

Power circuit ground fault recovered for 5 seconds. If the fault is remain existing. The fault is logged again. Auto reset is permitted up to 3 times within 1 hour. There after manual reset has to be done.

If the fault is occurred more than 3 times contact shed for further advice. Do not forget to write in the repair book.

Over Load Fault:- Tr. Alternator Field current is more than 280 Amps. Massage on Display Unit- 1027-Alternator Field over current FAULT. Restrictions: motoring prohibited dynamic brake prohibited” With Alarm bell switched on for 30 seconds.

Action by Loco Pilot:-

Bring throttle to IDLE. The fault is reset automatically. Reset message is displayed. Trouble shoots as per GFOLR trip in normal WDG3A locomotives. Alternator field over current is reset for 5 seconds.

If the fault is existing, the fault is logged again. Auto reset is permitted up to 3 times within 1 hour. There after manual reset has to be done.

If the fault is occurred more than 3 times contact shed for further advice. Do not forget to write in the repair book.

Hot Engine Alarm Fault:-

1. When water temperature raises up to 90o C.

Message on Display Unit -

2008 - Warning: ENGINE Temperature High. Reduce Power” for 5 seconds.

Alarm bell is switched ON continuously till temperature is less than 85o C.

Action by Loco Pilot:- If possible do fast pumping manually. Otherwise Power is de-rated by 20% per every degree of temperature raise from 90oC onwards.

910C- 20% power de-rated

920C- 40% power de-rated

930C- 60% power de-rated

940C- 80% power de-rated

Driver can work with reduced power up to 950C.

2. When water temperature is more than 95o C

Message on Display Unit -“1006 - HOT ENGINE. Can’t Power UP.

Restrictions: Motoring Prohibited Dynamic Brake Prohibited”

Along with buzzer continuously in addition to alarm bell.

GF and power contactors are dropped out. Engine RPM is

automatically raised to 8th notch irrespective of notch position.

If reset button is pressed or after 30 seconds

“2026 - HOT ENGINE. Can’t Power UP

Restrictions: Engine is running at 8th notch. Motoring Prohibited.

Dynamic Brake Prohibited. “Along with buzzer.

Action Taken by Loco Pilot:-

Apply train brakes. Wait till the water temperature is reduced below 90oC. Bring the master handle to IDLE. Engine speed reduces to IDLE automatically. Buzzer and message stops.

Auxiliary Power Unit

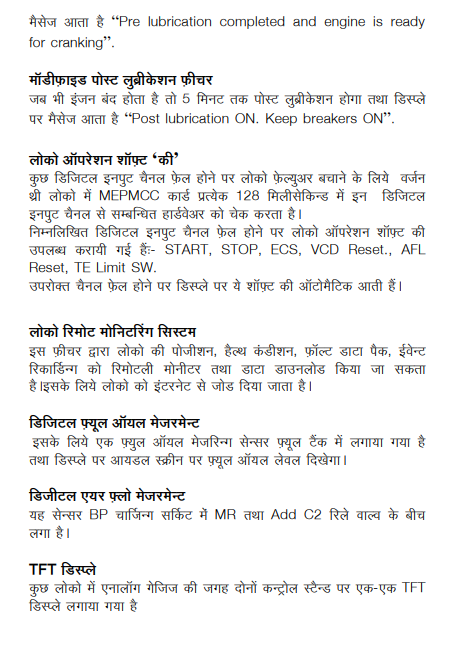

Procedure of Loco Handling and Its Precaution

1. Loco starting and braking system is similar to WDG3A (conventional).

2. Whenever needle of load meter showing restricted zone, do not ease the throttle, microprocessor will reduce power automatically.

3. When ever loco direction is require to change, loco should be stand still. When loco is running and reverse handle is operated, reverser will not change its position.

4. Do not ease the throttle when wheel slip occurs, microprocessor will reduce power automatically. Trouble shooting is similar as WDG3A (conventional). If trouble is because of drizzling /oily track /wet track than reduce the notch as per requirement.

5. When water temp become 900C, hot engine indication will come, do not reduce the notch, microprocessor will reduce power automatically (20% power will reduce automatically on each degree of rising water temp above 900C) when water temp become 950C, GFC and power contactor will drop automatically and loco power becomes zero, due to this load can be stall, apply train brake to avoid roll down. In this situation engine will race on 8th notch automatically for cooling the water, keep TH on idle and acknowledge the fault on display unit, wait till the engine speed comes on idle.

6. Whenever power ground or field over load occur, keep throttle on idle fault will reset automatically , if fault occurs three time in a hour reset it similarly. If fault occurs fourth time inform PCOR and reset it manually, trouble shooting is the same as WDG3A.

7. When there is trouble while train starting, ensure position of TE limit switch it should be in normal position otherwise tractive effort will be limited.

8. The loco which is provided with ‘cold engine speed limit feature’ is provided in that loco whenever lube oil temp less than 600C engine speed will not increase.

Additional features of Ver. 3.0

Power Setter:

Power setter is a feature to bring the rear locos to IDLE without going to rear locos and removing the MU cables.

Power Setter Enable Switch is provided like TE Limit Switch. Normally this switch is in ‘Disable’ position. When the driver wants single loco power, he will simply keeps this switch in ‘Enable’ position. Keeping this switch in ‘Enable’ position, Train Line Wire TL1 is energized in all the locos. So all the Rear locos work in IDLE, where as lead loco work as per notch position. The driver can work in higher notches and get fuel efficiency. While this switch is in ‘Enable’ position, ‘Power Setter Enabled’ message is displayed once in every 5 minutes. However Dynamic brake works normally in all locos and gets full control.

When driver wants both the locos power, he simply keeps this switch in ‘Disable’ Position. All the locos work normally.

Extended Dynamic Braking feature:

The maximum Dynamic Braking effort in Alco locomotives is in between 30 to 60 Km/h only.

Below 30 KMPH, the braking effort reduces since the grid current reduces due to TM armatures speed drops down.

In some steep gradient sections, the maximum speed is only 30KMPH. So these locos does not provide effective dynamic brake and pneumatic brakes have to be used to control the loco speed. To achieve higher braking effort in lower speeds this feature is implemented in ALCO locomotives.

At 21.5 Kmph (User settable) MEP energize Extended Dynamic Brake Relay (EDBR) to provide supply to 6 EDBC contactors. These pneumatic contactors are connected across certain portion of the grid resistors. Energizing these 6 contactors, the effective grid resistance will reduce. As the resistance is smaller, the grid current increases and results in higher braking effort at low speeds. To achieve single stage braking effort, 6 PCs has to be provided in the locomotive.

Rectifier fuse blown protection:

In power rectifiers, fuses are provided in series with each diode. In case of any diode short circuited, this fuse will blowout and the diode is isolated from the circuit.

This fuse is a special type of fuse, having a micro switch. The micro switch is operated through a lever when ever the fuse is blown out. In Ver.2, the fuse blown status is not monitored by MEP.

Only LED indication is given to driver. In Ver 3.0, one digital input is allotted for rectifier fuse blown protection and is connected to wire No. 111 in rectifier panel.

When this input is HIGH, the system declare a fault message “1066 –

This fuse is a special type of fuse, having a micro switch. The micro switch is operated through a lever when ever the fuse is blown out. In Ver.2, the fuse blown status is not monitored by MEP.

Only LED indication is given to driver. In Ver 3.0, one digital input is allotted for rectifier fuse blown protection and is connected to wire No. 111 in rectifier panel.

When this input is HIGH, the system declare a fault message “1066 –

Rectifier fuse blown, Restrictions: power limited to 4th notch”. Along with the message engine rpm and power both will be restricted to 4th notch. Whenever wire no. 111 is low, system will declare “1661- Rectifier fuse OK now”.

After fault recovery, engine rpm and power willraise as per notch position.

Power de-ration during power ground:

In Ver.2 when the TANGI value is more than 0.4 Amps, MEP declares fault message ‘Power Circuit Ground fault’

In Ver. 3 the notch power is de-rated if TANGI current is more than 0.4 Amps and still permit the loco to work with de-rated power.

This feature is very useful to avoid online failures and to protect power circuit from further damages. For every 0.1 Amp increment above 0.4 Amps of TANGI current, 20% of that notch power is de-rated.

The display shows a message “2021 – Power reduce due to power circuit ground”. The de-ration continues up to TANGI value reaches 0.9 Amps (user settable) and thereafter system declares a message “1007 - Power circuit ground fault” along with engine Idling and Power cut off.

Integrated Speedometer:

In Ver 3.0 system, no need of external stand alone speed recorder. MEP 660 system will generate an analog output signal based on the calculated speed from TM RPMs. The same signal will be fed to external analog meter to indicate the locomotive speed. Even 3 TM speed sensors are declared faulty, the speedometer indicates the loco speed without any trouble.

Protection against water pump failures:

In case of water pump failed, at present in Ver.2, there is no direct detection. Even though indirectly can be identified, there is no protection except power reduction. In Ver.03, water pressure sensor is provided to measure the outlet pressure of water pump. MEP-660 continuously monitors this water pump pressure along with LWS input and accordingly restrictions are implemented.

1. If the Water pressure is less than 0.4 Kg/cm², LWS input status is High and notch is >=3, fault message ‘Water pump not developing Pressure’ is logged.

2. If the water pressure is less than 0.4 Kg/cm², LWS input status is low ‘Low water level. Restrictions: Engine shut down’

3. If LWS input status is LOW and water pressure is > 0.6 Kg/cm² then ‘Low water switch defective’ fault message is logged.

Interface with Computer Control Braking (CCB):

Alco locomotives are so far equipped with IRAB brake system which is analog type pneumatic control. Computerized Control Brake system is a new brake system supplied by M/S Knorr Bremes in GM locomotives.

Lot of fail safe features are available with CCB and Railway wants to adopt the same brake system in Alco locomotives. With adoption of CCB in Alco locomotives, the following brake related equipments are removed.

Complete Brake panel is replaced with CCB.

AFL P1 | Eq.Pressure signal from CCB

AFL P2 | BP pressure signal from CCB

When ever Emergency Brake signal is received from CCB or based on EP & BP pressures, Auto flasher lights are switched ON.

BP, BCP pressure sensors. Signals are taken from CCB.

BKIV valve, Foot pedal Switch. PATB. VCD Valve – Penalty brake signal is communicated to CCB

CCB is connected to the MEP system via RS 485 communication.

If any fault in CCB, the same will be indicated in MEP 660 Display unit and it will apply brakes.

In MEP system, only fault message will appear but there is no controlling in CCB related issues.

CCB provides potential free contacts PCR which is equivalent to PCS. When ever CCB requires power cut off, these contacts are operated.

When ever MEP wants brake application, the brake signal is communicated to CCB and the brakes are applied by CCB.

Blended Braking system

So far with IRAB-1 brake system on Alco locomotives there is no provision to use both dynamic brake and pneumatic brakes simultaneously.

With computerized brake system it is possible to use combination of pneumatic brake and dynamic brake. Pneumatic brakes is substituted to the extend possible by dynamic brake to reduce wheel wear and cool running of wheels. In CCB fitted locomotives, Blended Brake switch is provided to enable / disable this feature by driver. Blended brake is possible only on lead locomotives. CCB does not permit Blended brake on Trail locomotives.

CCB is set as trail loco.

Emergency brake is initiated.

Dynamic brake is activated by driver.

Bail-Off request by driver.

Intelligent Low IDLE feature

The diesel Engine runs @ 400 RPM in IDLE and the fuel consumption is proportional to its RPM. Many times locos will be waiting for signal in station yards and they will be running in IDLE for longer periods. If the diesel engine is made to run at lower RPM under such long periods of waiting, lot of fuel saving can be achieved. Low IDLE feature is provided in Ver.2 to reduce the engine RPM to 350. If the engine runs in IDLE mode for more than 10 minutes, and in MEP LOW IDLE Flag is enabled, MEP energizes AV and DV digital outputs. If the Governor supports this combination, the Governor brings the engine RPM to 350.

However lube oil pressure is proportional to engine RPM and in some locos, diesel engine is getting shut down due to low lube oil pressure. To avoid unnecessary line failures, the end user fear to use this feature.

To overcome this unwanted engine shut down and still get fuel economy Intelligent Low Idle Feature has been introduced. In this feature When Engine is running in IDLE for more than 5 minutes, Low IDLE flag is enabled and Lube Oil Pressure is more than 1.7 Kg/cm² (User settable Parameter), then only MEP goes into Low IDLE mode. MEP energises AV and DV digital outputs and MCBG brings the engine rpm to 350 rpm (User settable). During Low IDLE mode operation, if Lube Oil Pressure is less than 1.2 Kg/cm² (User settable), MEP automatically revert back to IDLE mode. MEP de-energises AV and DV digital output and MCBG brings back engine RPM to 400 and the lube oil pressure increases.

LOW IDLE mode is linked to lube oil pressure value, engine does not shut down due to low lube oil pressure. So End user need not fear for unnecessary shutdown while working in low IDLE mode. There is sure of fuel savings with this feature.

In MEP-Ver.2 also this fire alerter system is available. Due to lack of digital inputs, single input has been connected to MEP. No identification weather the fire is in lead loco or trail loco.

In Ver. 3, for Fire Alert system two digital inputs are allotted to identify weather it is trail or lead loco.

The fire alerter provides two potential free contacts which energizes digital inputs FAS FB and TL 11 (MU wire).

If both FAS FB and TL 11 are high, system display a message “1073 - Fire occurred in loco. Check for fire and extinguish fire. Restrictions: Engine Shutdown”.

Along with message, power is cut off, engine is shut down and VCDR relay is switched OFF to apply brakes. If TL 11 alone is high display shows the message “2031 - Fire alarm occurred. Check loco thoroughly and reset fault. Restrictions: Cranking prohibited”.

Along with message, power is cut off, engine is shut down. Brake valve gets supply through TL20 wire.

Pre / Post Lubrication feature:

1. Pre Lubrication:

Both the features are implemented in MEP-660 Ver.2 itself. With field experience, slight logics are changed in Ver.3 Pre Lubrication is avoided if the engine is re-cranked with in 30 minutes from the last shut down time. This is because, sufficient lubrication film will available with in 30 minutes. If 30 minutes is lapsed, engine cranks after pre lubrication. In case of any cranking restrictions, the same is displayed before starting pre-lubrication. A count down timer is shown on the display unit, to indicate the time left for cranking. After completion of pre lubrication, display shows “Pre lubrication completed and engine is ready for cranking”. Engine cranks normally.

2. Post Lubrication

In MEP Ver.2 the Post lubrication is carried out only when the engine shut down through STOP push button.

Where as in MEP Ver.3, post lubrication is carried out for any type of engine shutdown. Post lubrication is for 5 minutes (user settable).

During Post lubrication, display will shows a message “Post lubrication ON. Keep breakers ON”.

In Ver. 2, MCOS switches are available to isolate a defective traction motor. In Ver. 3, MCOS switches are not available, the same function can execute through Display unit.

Main Menu

4 TM cut out

TM status screen is displayed.

Change / F3 TM1 is highlighted. Use arrow keys to select TM Cut out / F3 to change the status.

some digital input channel failure is causing a line failure of the locomotive. There is no fault tolerance for these digital input channel failures in Ver.2. In order to avoid On-line failures due to some digital input channel failure and clearly identify that the problem is with hardware, self check routine for digital input channels is provided in MEP-660 Ver. 3. MEPMCC card checks the health status of these channels at regular intervals. Loco operation soft keys:

If any channel is found defective: system logs a fault that particular digital input is defective. If alternate logic is available, the system allows normal operation of loco. Where alternate logic is not available, system permits loco with some restrictions. Where user selection is essential for that input, soft keys are provided through display to toggle the status of that input in the software.

The following are the digital input channels where soft keys are

provided:

START, STOP, ECS, VCD Reset, AFL Reset, TE Limit SW. Display shows the soft key screen automatically.

After fault recovery, engine rpm and power willraise as per notch position.

Power de-ration during power ground:

In Ver.2 when the TANGI value is more than 0.4 Amps, MEP declares fault message ‘Power Circuit Ground fault’

In Ver. 3 the notch power is de-rated if TANGI current is more than 0.4 Amps and still permit the loco to work with de-rated power.

This feature is very useful to avoid online failures and to protect power circuit from further damages. For every 0.1 Amp increment above 0.4 Amps of TANGI current, 20% of that notch power is de-rated.

The display shows a message “2021 – Power reduce due to power circuit ground”. The de-ration continues up to TANGI value reaches 0.9 Amps (user settable) and thereafter system declares a message “1007 - Power circuit ground fault” along with engine Idling and Power cut off.

Integrated Speedometer:

In Ver 3.0 system, no need of external stand alone speed recorder. MEP 660 system will generate an analog output signal based on the calculated speed from TM RPMs. The same signal will be fed to external analog meter to indicate the locomotive speed. Even 3 TM speed sensors are declared faulty, the speedometer indicates the loco speed without any trouble.

Protection against water pump failures:

In case of water pump failed, at present in Ver.2, there is no direct detection. Even though indirectly can be identified, there is no protection except power reduction. In Ver.03, water pressure sensor is provided to measure the outlet pressure of water pump. MEP-660 continuously monitors this water pump pressure along with LWS input and accordingly restrictions are implemented.

1. If the Water pressure is less than 0.4 Kg/cm², LWS input status is High and notch is >=3, fault message ‘Water pump not developing Pressure’ is logged.

2. If the water pressure is less than 0.4 Kg/cm², LWS input status is low ‘Low water level. Restrictions: Engine shut down’

3. If LWS input status is LOW and water pressure is > 0.6 Kg/cm² then ‘Low water switch defective’ fault message is logged.

Interface with Computer Control Braking (CCB):

Alco locomotives are so far equipped with IRAB brake system which is analog type pneumatic control. Computerized Control Brake system is a new brake system supplied by M/S Knorr Bremes in GM locomotives.

Lot of fail safe features are available with CCB and Railway wants to adopt the same brake system in Alco locomotives. With adoption of CCB in Alco locomotives, the following brake related equipments are removed.

Complete Brake panel is replaced with CCB.

AFL P1 | Eq.Pressure signal from CCB

AFL P2 | BP pressure signal from CCB

When ever Emergency Brake signal is received from CCB or based on EP & BP pressures, Auto flasher lights are switched ON.

BP, BCP pressure sensors. Signals are taken from CCB.

BKIV valve, Foot pedal Switch. PATB. VCD Valve – Penalty brake signal is communicated to CCB

CCB is connected to the MEP system via RS 485 communication.

If any fault in CCB, the same will be indicated in MEP 660 Display unit and it will apply brakes.

In MEP system, only fault message will appear but there is no controlling in CCB related issues.

CCB provides potential free contacts PCR which is equivalent to PCS. When ever CCB requires power cut off, these contacts are operated.

When ever MEP wants brake application, the brake signal is communicated to CCB and the brakes are applied by CCB.

Blended Braking system

So far with IRAB-1 brake system on Alco locomotives there is no provision to use both dynamic brake and pneumatic brakes simultaneously.

With computerized brake system it is possible to use combination of pneumatic brake and dynamic brake. Pneumatic brakes is substituted to the extend possible by dynamic brake to reduce wheel wear and cool running of wheels. In CCB fitted locomotives, Blended Brake switch is provided to enable / disable this feature by driver. Blended brake is possible only on lead locomotives. CCB does not permit Blended brake on Trail locomotives.

CCB is set as trail loco.

Emergency brake is initiated.

Dynamic brake is activated by driver.

Bail-Off request by driver.

Intelligent Low IDLE feature

The diesel Engine runs @ 400 RPM in IDLE and the fuel consumption is proportional to its RPM. Many times locos will be waiting for signal in station yards and they will be running in IDLE for longer periods. If the diesel engine is made to run at lower RPM under such long periods of waiting, lot of fuel saving can be achieved. Low IDLE feature is provided in Ver.2 to reduce the engine RPM to 350. If the engine runs in IDLE mode for more than 10 minutes, and in MEP LOW IDLE Flag is enabled, MEP energizes AV and DV digital outputs. If the Governor supports this combination, the Governor brings the engine RPM to 350.

However lube oil pressure is proportional to engine RPM and in some locos, diesel engine is getting shut down due to low lube oil pressure. To avoid unnecessary line failures, the end user fear to use this feature.

To overcome this unwanted engine shut down and still get fuel economy Intelligent Low Idle Feature has been introduced. In this feature When Engine is running in IDLE for more than 5 minutes, Low IDLE flag is enabled and Lube Oil Pressure is more than 1.7 Kg/cm² (User settable Parameter), then only MEP goes into Low IDLE mode. MEP energises AV and DV digital outputs and MCBG brings the engine rpm to 350 rpm (User settable). During Low IDLE mode operation, if Lube Oil Pressure is less than 1.2 Kg/cm² (User settable), MEP automatically revert back to IDLE mode. MEP de-energises AV and DV digital output and MCBG brings back engine RPM to 400 and the lube oil pressure increases.

LOW IDLE mode is linked to lube oil pressure value, engine does not shut down due to low lube oil pressure. So End user need not fear for unnecessary shutdown while working in low IDLE mode. There is sure of fuel savings with this feature.

Fire Alerter System:

In Ver. 3, for Fire Alert system two digital inputs are allotted to identify weather it is trail or lead loco.

The fire alerter provides two potential free contacts which energizes digital inputs FAS FB and TL 11 (MU wire).

If both FAS FB and TL 11 are high, system display a message “1073 - Fire occurred in loco. Check for fire and extinguish fire. Restrictions: Engine Shutdown”.

Along with message, power is cut off, engine is shut down and VCDR relay is switched OFF to apply brakes. If TL 11 alone is high display shows the message “2031 - Fire alarm occurred. Check loco thoroughly and reset fault. Restrictions: Cranking prohibited”.

Along with message, power is cut off, engine is shut down. Brake valve gets supply through TL20 wire.

Pre / Post Lubrication feature:

1. Pre Lubrication:

Both the features are implemented in MEP-660 Ver.2 itself. With field experience, slight logics are changed in Ver.3 Pre Lubrication is avoided if the engine is re-cranked with in 30 minutes from the last shut down time. This is because, sufficient lubrication film will available with in 30 minutes. If 30 minutes is lapsed, engine cranks after pre lubrication. In case of any cranking restrictions, the same is displayed before starting pre-lubrication. A count down timer is shown on the display unit, to indicate the time left for cranking. After completion of pre lubrication, display shows “Pre lubrication completed and engine is ready for cranking”. Engine cranks normally.

2. Post Lubrication

In MEP Ver.2 the Post lubrication is carried out only when the engine shut down through STOP push button.

Where as in MEP Ver.3, post lubrication is carried out for any type of engine shutdown. Post lubrication is for 5 minutes (user settable).

During Post lubrication, display will shows a message “Post lubrication ON. Keep breakers ON”.

TM cut out / cut in through Display

Main Menu

4 TM cut out

TM status screen is displayed.

Change / F3 TM1 is highlighted. Use arrow keys to select TM Cut out / F3 to change the status.

Loco operation soft keys

If any channel is found defective: system logs a fault that particular digital input is defective. If alternate logic is available, the system allows normal operation of loco. Where alternate logic is not available, system permits loco with some restrictions. Where user selection is essential for that input, soft keys are provided through display to toggle the status of that input in the software.

The following are the digital input channels where soft keys are

provided:

START, STOP, ECS, VCD Reset, AFL Reset, TE Limit SW. Display shows the soft key screen automatically.