Main Components of ICF Bogie

UNDERFRAME:-

i) Sole bar

ii) Head stock

iii) Transom

iv) Longitudinal bar

PRIMARY SUSPENSION:-

i) Dash pot

ii) Dash pot spring

iii) Dash pot protection tube

iv) Air vent screw

v) Axle box safety bolt

vi) Axle box wing & lug

vii) Safety strap & safety loop

SECONDARY SUSPENSION:-

i) Bogie bolster upper plank

ii) Bogie bolster lower plank

iii) Suspension link, link pin & stone

iv) Bolster spring

v) Vertical shock absorber

vi) Safety strap & safety loop

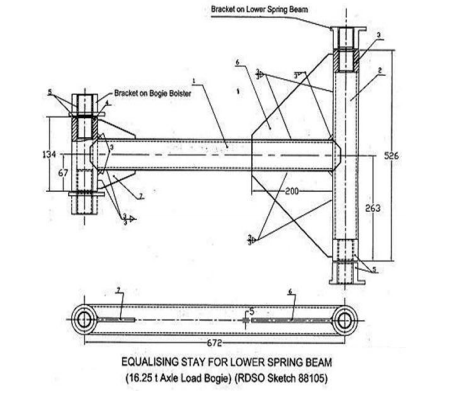

vii) Equalizing stay rod

viii) Anchor link

ix) Centre pivot cotter, split pin & cup

x) Silent block

xi) Side bearer housing

xii) Side bearer metal plate

BRAKE GEAR:-

i) Brake beam

ii) Brake beam hanger & safety bracket

iii) Brake safety wire rope

iv) Brake shoe & key

v) Floating lever

vi) Curved pull rod

vii) Equalizing truss bar

viii) Palm end

Features of ICF All Coil Bogie:-

1) Bogie is designed to run on Indian Broad Gauge Track (1676 mm).

2) Provision of coil spring at primary & secondary suspension so that bogie is known as All Coil Bogie.

3) Bogie Head Stock is provided with pressed T- section and sole bar is with pressed I-section, but at the location of link brackets it is in box section.

4) Transom – Previously it was in C-section but now a day it is in Box section to be more robust.

5) Wheel Base of bogie is 2896 mm.

6) Weight Transmission - By 2 side bearer located at distance of 1600 mm.

7) Guidance of bogie Lateral and Longitudinal both with the use of Centre Pivot pin located at the centre of bolster.

8) Wheel Guidance lateral and longitudinal both with the use of 2 nos. of Dash Pot guide per Axle Box Wings welded at sole bar.

9) Axle Capacity - 13 T – For Non A/C coach 16 T – for A/C coach and WLRRM coach

10) Roller Bearing – Double Roll Self Aligned Spherical Roller Bearing.

11) Axle – Solid and Straight

12) Wheel Diameter – New – 915 mm Condemn – 825 mm (workshop release size - 833 mm). Ref: Rly. Board’s Letter No. G2/ M(c)/151/2 vol. - V dated 25/01/2011

13) Shock Absorber – Provided on Secondary suspension between Bolster and lower plank (2 nos. of each Bogie).2 nos. of lateral shock absorber are being provided in ICF Bogie to be utilized for Hybrid Coach.

14) Vertical Hydraulic Dampers – 2 nos. per Axle Box Vertical telescopic hydraulic Dashpots are provided.

15) Fitment of brake block - Clasp type brake block arrangement is provided with the use of brake shoe head and brake beam.

16) 2 nos. equalizing stay rods per bogie are utilized to maintain the distance between both the lower planks and to maintain lateral thrust occurring during run.

17) Provision of Anchor link – 2 nos. per bogie with the provision of silent bushes are provided diagonally between bogie transom and bolster to work as a media to transmit the draw and braking force from trolley to body and body to trolley vice versa.

18) Piston Stroke – In conventional type Air Brake system 90 ± 10 mm and in BMBC within 32mm should be maintained.

19) Provision of Running Clearance:-

a) ‘A’ Clearance: - For 13 T – 43 +0/-3 mm, For 16 T – 27 +0/-3 mm It is a clearance to be provided between axle box crown & safety bolt.

b) ‘B’ Clearance: - It is a clearance to be provided between bolster top & bottom of sole bar that should be 40 +/- 5 mm to all type of bogie.

20) Riding index: - ICF bogie – 3.25 to 3.50

21) Truss bar Hanger: - Strength with double eye hole. New length - 235 mm. Old length – 205 mm 22) Journal Size: - Dia. – 120x113.5 mm (sleeve mounted), 120x130.5 mm (direct mounted)

23) Journal Centre: - 2159.5 mm

24) Speed: - Fit to run up to 110 kmph. (Trial has been conducted up to 140 kmph.

Weight Transmission of ICF Coach:

Draft Force Transmission of ICF Coach

Braking Force Transmission of ICF Bogie to Body

Axle Box Guide with Dashpot Arrangement

Axle box guides are of cylindrical type welded to the bottom flanges of the bogie side frame with close dimensional accuracy. These guides together with lower spring seats located over the axle box wings house the axle box springs and also serve as shock absorbers. These guides are fitted with guide caps having nine holes of diameter 5 mm equidistant through which oil in the lower spring seat passes under pressure during dynamic oscillation of coach and provide necessary damping to primary suspension to enhance riding quality of coach.

This type of rigid axle box guide arrangement eliminates any longitudinal or transverse relative movement between the axles and the bogie frame. The quantity of oil required for maintaining 40 mm oil level above the guide cap in modified arrangement is approximately 1.6 litres and in unmodified arrangement is approximately 1.4 litres. As it is not possible in open line to distinguish between modified and unmodified arrangements, 40 mm oil level is standardized for both.

Air Vent Screws: On the bogie side frames, directly above the dash-pots, tapped holes are provided for replenishing oil in the dash pots. Special screws with copper asbestos washers are screwed on the tapped hole to make it air tight.

Bogie Bolster Suspension: The bolster rests on the bolster coil springs - two at each end, located on the lower spring beam which is suspended from the bogie side frame by means of bolster-springsuspension (BSS) hangers on either side.

Springs: In ICF bogie, helical springs are used in both primary and secondary suspension. The springs are manufactured from peeled and centre less ground bar of chrome vanadium/chrome molybdenum steel.

Centre pivot arrangement: The centre pivot pin joins the body with the bogie and transmits the tractive and braking forces. It does not transmit any vertical load. It is equipped with rubber silent block bushes which tend to centralize the bogies with respect to the body and, to some extent control and damp the angular oscillations of the bogies.

Side Bearers: The side bearer arrangement consists of a machined steel wearing plate immersed in an oil bath and a floating bronzewearing piece with a spherical top surface, kept on both sides of 23 the bogie bolster. The coach body rests on the top spherical surface of these bronze-wearing pieces through the top side bearer at the bottom of the body-bolster. The whole arrangement is provided with a cover to prevent entry of dust in the oil sump.

Wear limit for wearing plate:

New size: 10 mm Condemning size : 8.5 mm

Wear limit for wearing piece:

New size: 45 mm Condemning size : 42 mm

Anchor Links: The floating bogie bolster which supports the coach body is held in position longitudinally by the anchor links which are pinned to the bolster sides and the bogie Transoms. 24 One anchor link is provided on each side of the bolster diagonally. The links can accommodate vertical movement to permit the bolster to rise and fall. The links prevent any relative longitudinal movement between the bogie frame and coach body. They are designed to take the tractive and braking forces. The anchor links are fitted with silent block bushes.

Silent Block: This is a synthetic rubber bush fitted in anchor link and centre pivot of ICF bogies to transmit force without shock and reduce noise.

Bolster Spring Suspension (BSS) Hangers: In the secondary suspension, the bolster is supported on helical coil springs which are placed on the lower spring plank. The lower spring plank is suspended from the bogie side frame through BSS hangers on hanger blocks.

Shock Absorbers: Hydraulic shock absorbers with capacity of 600 kg at a speed of 10 cm/sec. are fitted on 13 ton bogie & 900 kg at a speed of 10 cm/sec. are fitted on 16 ton bogie work in parallel with the bolster springs to provide damping for vertical oscillations.

Equalizing Stays: This device has been provided on bogies between the lower spring plank and the bolster to prevent lateral thrust on the bolster springs as these springs are not designed to take the lateral forces. These links have pin connections at both ends and, therefore, can move vertically.

2.2.3 Direct Mounted Roller Bearing Arrangement

Double Row Self Aligned Spherical Roller Bearing

Roller bearing defects

Flaked, pitted, Burnt, Dented, Excessively worn and seized rollers. Smearing, Cage broken, Corrosion, Locking stud loose or broken, Over greasing, Less grease & Contaminated grease, Felt ring damaged/perished, Retainer ring broken, Excessive lateral play.

Inspection of other components related to Roller Bearing

The following components other than roller bearing should be inspected during roller bearing maintenance in the workshop. Axle end holes, End locking plates, End locking bolts, Retaining Ring, Collar, Felt ring, Rear and Front Cover, Axle box housing