DIESEL LOCO - Multiple Unit

When two or more locomotive are coupled mechanically, electrically and pneumatically with each other and controlled by a single loco pilot, it is called multiple unit.

Procedure:

1. Check and engine start the locos individually before making multiple unit.

2. Adjust all the pressure related to break system.

3. Carry out vacuum test, orifice test and leak off test separately of each loco.

4. Couple the all locos with CBC and lock it with lock pin.

5. Couple electrical jumper cable between the locos.

6. Couple following pipes between the locos –

- Brake pipe

- Feed pipe

- Brake cylinder equalizing pipe

- MR. equalizing pipe • Vacuum hose pipe

- Brake pipe angle cut out cock

- Feed pipe angle cut out cock

- Brake cylinder equalizing pipe cut out cock

- MR equalizing pipe cut out cock

- Open A9 COC of Working control stand and rest of all other non working control stand to be closed.

- Open SA9 COC of Working control stand and rest of all other non working control stand to be closed.

- Open the ¾” COC in leading loco and close in rest of all trailing locos.

- Keep MU2B in lead position of leading loco and in trail position of all trailing locos.

- Open the A1 differential pilot valve and HB5 COC of all locos. • Open banking cut out cock in all locos.

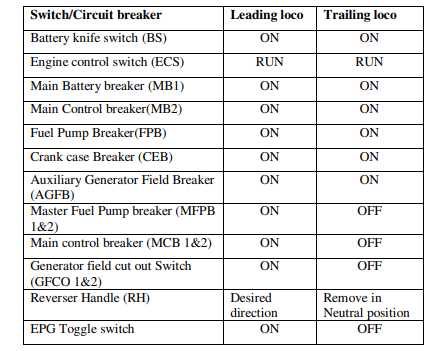

9. Keep the position of circuit breakers and switches in loco pilot cab as

10. Following to be checked after preparing the MU.

Working of Train with Dead Leading Loco -

While working MU if leading loco failed (No problem in under truck and brake system) then train can be worked from the dead leading loco by adopting following procedure –

1. On dead leading loco, put OFF all the circuit breakers of front panel except MB1, 2.

2. Put ECS in idle position.

3. No any change in position of switch, circuit breakers of control stand in leading loco.

4. Do not change position of circuit breakers/switches of trailing loco.

- Dropping of the BP pressure by A9 and its recreation.

- Dropping of the vacuum by A9 and its recreation.

- Application and releasing of loco brakes by SA9.

- As per throttle notch position, the speed of all engines should be increase and decrease simultaneously.

- Movements of all loco as per reverser handle position.

- Raising of all engines when selector handle kept in braking position.

Working of Train with Dead Leading Loco -

While working MU if leading loco failed (No problem in under truck and brake system) then train can be worked from the dead leading loco by adopting following procedure –

1. On dead leading loco, put OFF all the circuit breakers of front panel except MB1, 2.

2. Put ECS in idle position.

3. No any change in position of switch, circuit breakers of control stand in leading loco.

4. Do not change position of circuit breakers/switches of trailing loco.

5. In air brake train, do not change position of valves / COC of brake system.

6. In vacuum brake train, Keep MU2B in lead position of trailing loco and close BC equalizing cock between the locos. Do not change position of valves / COC of brake system of leading loco.

7. Before starting the train ensures dropping /recreation of BP pressure and vacuum by A9.

Driving Cab Changing Procedure in Multiple Unit:

A) On incoming leading loco which is require to make trailing

E) Ensure normal working of all the Loco.

6. In vacuum brake train, Keep MU2B in lead position of trailing loco and close BC equalizing cock between the locos. Do not change position of valves / COC of brake system of leading loco.

7. Before starting the train ensures dropping /recreation of BP pressure and vacuum by A9.

Driving Cab Changing Procedure in Multiple Unit:

A) On incoming leading loco which is require to make trailing

- Apply loco brake by SA9 and remove its handle.

- Close the A9 COC and remove its handle in release position.

- Remove reverser handle in neutral position.

- Insert SA9 handle on working control stand and apply loco brake by it. (Open SA9 COC of working control stand if provided)

- Insert A9 handle in release position of working control stand and open its COC.

- Put MU2B on lead position.

- Open ¾” COC.

- Put ON MCB-1 & 2.

- Put ON MFPB- 1 & 2.

- Release the SA9.

- Close SA9 COC of working control stand if provided.

- Put MU2B on trail position.

- Close ¾” COC.

- Put OFF GFCO- 1 & 2.

- Put OFF MCB-1 & 2.

- Put OFF MFPB- 1 & 2.

E) Ensure normal working of all the Loco.