DIESEL LOCO - WDM2 Locomotive

This loco is designed for mixed service.

General data

Engine Horse Power 2600 HP

Loco Horse Power 2400 HP

Maximum Speed 120 km/h

Weight 112.8

T Axle Load 18.8 T

Tractive Effort 30.5 T

Brake System 28LAV1

Transition 30, 50, 80 km/h

Generator DC

Type of Diesel Engine 251B

Engine Idle Speed 400 rpm

Engine 8th notch Speed 1000 rpm

OSTA Setting 1130 ±20 rpm

Power Contactor 9

Reverser 2

BKT 2

Center Pivot 2

Side Load Bearer 4

Length of Loco 17120 mm

Buffer height 1030-1105 mm

Locomotive Driving Right Hand

Bogie Co-Co Type Trimount

Traction Motor DC Series Motor

Engine Governor EH / WW

Crankshaft Overlap Period 123o

Locomotive Series 16, 17, 18

Main Compartments of WDM2 Loco

1 Nose compartment.

1 Nose compartment.

2 Loco Pilot cab

3 Control compartment

4 Generator room

5 Engine room

6 Expressor room

7 Radiator room

8 Under truck

Nose Compartment -

The following equipments are provided

Battery knife switch BKBL motor

Battery knife switch BKBL motor

Braking grids NS1 reducing valve & COC

Control Reservoir Horn COC

Wipers COC VA1 release valve

VA1B Control Valve Vacuum check

valve GD80D Filter

GD80E Filter 2 Sand Boxes Banking COC

COC with strainer A1 Differential Pilot Valve &COC

On the outer wall of Nose Compartment Head light, Marker light, Flasher light and multiple unit jumper cables are provided.

Compartments of WDM2 Locomotive

1. Nose Compartment

Battery knife switch (BS) VA1 B Control valve

Dynamic Braking Blower motor ( BKBL) VA1 Release valve

Dynamic braking Grids Vacuum check valve

GD-80D Filter GD-80E Filter

Banking cutout cock COC with strainer

Two sand boxes Horn and wiper COC

A-1 Differential pilot valve, its COC and reservoir

NS-1 Reducing valve and its COC

Control Reservoir with drain cock

On outer wall of Nose compartment head light, flasher light marker light and multiple unit jumper couples are provides.

2. Loco Pilot Cab

On both control stand

A-9 valve SA- 9 valve

Throttle Handle (TH) Selector Handle (H)

Reverser Handle (RH) Load meter

Vacuum Gauge Lighting switches

Head light switch (HLS) Flasher light control box

Indication Lamp panel Horn & Sander switch

Brake pipe or Brake cylinder Pressure Gauge

Auxiliary Reservoir and MR pressure Gauge

Multiple unit shut down switch (MUSD)

Master Fuel pump Breaker (MFPB)

Generator Field cut out switch (GFCO)

Main control breaker MCB

On Right Control On Left Control Stand

HS4 valve HB5 valve & its COC

Vacuum control pressure gauge PCS

MU2B Valve H5A valve& its COC

F1 selector valve Electrical speedometer

Wheel slip buzzer Mechanical speedometer 28VB valve D1 Pilot valve

¾” COC, Hand brake, Control air pressure, LOP, FOP, BAP gauges, OPS D1 emergency flap valve

valve GD80D Filter

GD80E Filter 2 Sand Boxes Banking COC

COC with strainer A1 Differential Pilot Valve &COC

On the outer wall of Nose Compartment Head light, Marker light, Flasher light and multiple unit jumper cables are provided.

Compartments of WDM2 Locomotive

1. Nose Compartment

Battery knife switch (BS) VA1 B Control valve

Dynamic Braking Blower motor ( BKBL) VA1 Release valve

Dynamic braking Grids Vacuum check valve

GD-80D Filter GD-80E Filter

Banking cutout cock COC with strainer

Two sand boxes Horn and wiper COC

A-1 Differential pilot valve, its COC and reservoir

NS-1 Reducing valve and its COC

Control Reservoir with drain cock

On outer wall of Nose compartment head light, flasher light marker light and multiple unit jumper couples are provides.

2. Loco Pilot Cab

On both control stand

A-9 valve SA- 9 valve

Throttle Handle (TH) Selector Handle (H)

Reverser Handle (RH) Load meter

Vacuum Gauge Lighting switches

Head light switch (HLS) Flasher light control box

Indication Lamp panel Horn & Sander switch

Brake pipe or Brake cylinder Pressure Gauge

Auxiliary Reservoir and MR pressure Gauge

Multiple unit shut down switch (MUSD)

Master Fuel pump Breaker (MFPB)

Generator Field cut out switch (GFCO)

Main control breaker MCB

On Right Control On Left Control Stand

HS4 valve HB5 valve & its COC

Vacuum control pressure gauge PCS

MU2B Valve H5A valve& its COC

F1 selector valve Electrical speedometer

Wheel slip buzzer Mechanical speedometer 28VB valve D1 Pilot valve

¾” COC, Hand brake, Control air pressure, LOP, FOP, BAP gauges, OPS D1 emergency flap valve

3. Control Compartment.

On front panel

Dome light circuit Breaker (DLCB)

Head Light circuit Breaker (HLB)

Cab light circuit Breaker Battery ammeter Battery Breaker (MB1)

Control Breaker (MB2

Auxiliary Generator Field Breaker(AGFB)

Fuel pump Breaker(FPB)

Crankcase Exhauster Breaker (CCEB)

Start Button ,Stop Button Engine control switch ( ECS)

Motor cut out switch (MCO)

Compartment light switch

Ground Relay reset knob

Inside front panel - Signal Relay (SR), Engine speed Relay (1,2,3,4,), Field shunt ,Relay (FSR), Transition Relay (TR), Safety Auxiliary Relay(SAR), Dead Means Relay(DMR), Breaking Relay (BKR), Ground Relay(GR), Generator Field contactor(GFC), Reverse control panel (RCD), Fuel pump contactor(FPC), Voltage Regulating panel(VRP), Transition panel (TRP), Engine Control panel(ECP), Excitation panel, Wheel slip Relay(WSR-1,2,3), Transition Excitation transformer (TET)

Power Contactors(P31,S31,P22,P21,S21,P32,P2,S1,P1), Cranking contactor (CK1,CK2), Braking and Traction contactor (BKT-1, 2) Reverser contactor (REV-1, 2), Load Ammeter shunt (LAS) Armature Current control Reactor (ACCR).

Back Panel- Radiator fan Contactor (R1&R2), Temperature Control Resistance (TCR), Voltage Dividing Panel (VDP), Gauge Lamp Resistance, Generator Field Resistance (GFR), Wheel slips Relay Resistance (WSRR), Field control Panel(FCP), Field shunt Relay Resistance (FSRR), Head light Resistance (HLPR), Voltage Regulating Current limit shunt (VRCLS), Arc suppression Rectifier(CPR-1,2)

4. Generator Room

Main Generator, Auxiliary Generator, Exciter Generator, FTTM, Generator Gear Case and its dip stick gauge

5. Engine Room

251-B type diesel engine

Fuel injection pump

High Pressure Line

On front panel

Dome light circuit Breaker (DLCB)

Head Light circuit Breaker (HLB)

Cab light circuit Breaker Battery ammeter Battery Breaker (MB1)

Control Breaker (MB2

Auxiliary Generator Field Breaker(AGFB)

Fuel pump Breaker(FPB)

Crankcase Exhauster Breaker (CCEB)

Start Button ,Stop Button Engine control switch ( ECS)

Motor cut out switch (MCO)

Compartment light switch

Ground Relay reset knob

Inside front panel - Signal Relay (SR), Engine speed Relay (1,2,3,4,), Field shunt ,Relay (FSR), Transition Relay (TR), Safety Auxiliary Relay(SAR), Dead Means Relay(DMR), Breaking Relay (BKR), Ground Relay(GR), Generator Field contactor(GFC), Reverse control panel (RCD), Fuel pump contactor(FPC), Voltage Regulating panel(VRP), Transition panel (TRP), Engine Control panel(ECP), Excitation panel, Wheel slip Relay(WSR-1,2,3), Transition Excitation transformer (TET)

Power Contactors(P31,S31,P22,P21,S21,P32,P2,S1,P1), Cranking contactor (CK1,CK2), Braking and Traction contactor (BKT-1, 2) Reverser contactor (REV-1, 2), Load Ammeter shunt (LAS) Armature Current control Reactor (ACCR).

Back Panel- Radiator fan Contactor (R1&R2), Temperature Control Resistance (TCR), Voltage Dividing Panel (VDP), Gauge Lamp Resistance, Generator Field Resistance (GFR), Wheel slips Relay Resistance (WSRR), Field control Panel(FCP), Field shunt Relay Resistance (FSRR), Head light Resistance (HLPR), Voltage Regulating Current limit shunt (VRCLS), Arc suppression Rectifier(CPR-1,2)

4. Generator Room

Main Generator, Auxiliary Generator, Exciter Generator, FTTM, Generator Gear Case and its dip stick gauge

5. Engine Room

251-B type diesel engine

Fuel injection pump

High Pressure Line

Water Jumper pipe, Water riser pipe

Inlet elbow, Exhaust elbow, Exhaust manifold, Cross over pipe

On engine right side

Engine Governor Tacho Generator

Lube oil Dipstick gauge Crankcase Explosion Door

Primary filter Secondary filter

OSTA Fuel oil Relief valve

Bubble collector Lube secondary Header

Right side fuel oil gallery

On engine left hand side

Crank case Exhauster Motor Fuel oil Regulating valve

Lube oil strainer Bubble collector

Lube oil Main Header Lube secondary Header

Left side fuel oil gallery

On free end

Turbo super charger After cooler

Water pump Lube oil pump

6. Expressor Room

Expressor Fuel pump motor

Water drain cock Air maize oil bath filter

Car body filters ETS-1, 2, 3.

Water temperature gauge LWS& its Test cock

Lube oil relief valve Lube oil regulating valve

NS-16 governor & its cock, Norton filter

7. Radiator Room

Lube oil by pass valve Lube oil cooler

Radiator core Radiator fan

Sand boxes Expansion tank no. 1&2

Right Angle Gear Box Eddy current clutch coil (ECC)

Lube oil filter drum and its drain cocks

Rear Truck Traction Motor Blower (RTTM)

On outer wall of radiator Room Head light flasher light, water level gauge, marker light and multiple unit jumpers are provided.

8.Under Truck

CO-CO tri mount bogie Front truck

Rear Truck Center Pivot

Side load Bearer Helical Spring

Equalizing beam Axle Box

Axle Journal Traction motor

Nose pad Pinion Gear

Axle Gear Traction Motor Gear case

Inlet elbow, Exhaust elbow, Exhaust manifold, Cross over pipe

On engine right side

Engine Governor Tacho Generator

Lube oil Dipstick gauge Crankcase Explosion Door

Primary filter Secondary filter

OSTA Fuel oil Relief valve

Bubble collector Lube secondary Header

Right side fuel oil gallery

On engine left hand side

Crank case Exhauster Motor Fuel oil Regulating valve

Lube oil strainer Bubble collector

Lube oil Main Header Lube secondary Header

Left side fuel oil gallery

On free end

Turbo super charger After cooler

Water pump Lube oil pump

6. Expressor Room

Expressor Fuel pump motor

Water drain cock Air maize oil bath filter

Car body filters ETS-1, 2, 3.

Water temperature gauge LWS& its Test cock

Lube oil relief valve Lube oil regulating valve

NS-16 governor & its cock, Norton filter

7. Radiator Room

Lube oil by pass valve Lube oil cooler

Radiator core Radiator fan

Sand boxes Expansion tank no. 1&2

Right Angle Gear Box Eddy current clutch coil (ECC)

Lube oil filter drum and its drain cocks

Rear Truck Traction Motor Blower (RTTM)

On outer wall of radiator Room Head light flasher light, water level gauge, marker light and multiple unit jumpers are provided.

8.Under Truck

CO-CO tri mount bogie Front truck

Rear Truck Center Pivot

Side load Bearer Helical Spring

Equalizing beam Axle Box

Axle Journal Traction motor

Nose pad Pinion Gear

Axle Gear Traction Motor Gear case

Brake cylinder Brake assembly

Wheels Sanding Arrangement

Rail Guard Cattle Guard

Pipes of Brake System Buffers

Center Buffer coupler Fuel Tank

M.R Tank Axle Generator

Mechanical speedometer sensor Brake system

valves Hand brake chain

Co-Co tri mount bogie is fitted in under truck of WDM2 loco. The short hood side bogie is called front truck and the long hood side bogie is called Rear Truck.

Bogie frame is made of cast steel, on each bogie one center pivot and two side load bearer are provided .The whole load of super structure is divided on these center pivots and side load bearer, each center pivot carries 30% load and side load bearer carries 10% each. On each axle journal, one axle box is fitted. The load is transferred on axle box through helical spring on equalizing beam. There is one set of two equalizing beams, these two beams are tied together by a tie bolt and on each set of the equalizing beam one spring chair is provided on which two sets helical springs are mounted. One set of helical spring having snubber, because of spring and snubber vibration and jerks on the frame are minimized. In this way both bogies having 16 equalizing beams, 16 spring sets and snubber (08 no.).

Traction motor is mounted on each axle with the help of suspension bearing and other end of TM is placed on cross member embarked nose pads. For lubrication of suspension bearing wick pads are provided. Lower end of wick pad is dipped in oil and upper end supplies oil to bearing and axle. On each axle two numbers of suspension bearings are provided, thus total number of suspension bearings is 12.

A 65 teeth drive gear is provided on each axle and a 18 teeth pinion gear fitted on armature of Traction motor is matched with axle gear. This gear assembly is placed in traction motor gear case; it is made up in two parts and fitted together with C-clamp & flange bolts. This gear case is fitted on TM yoke with three foundation bolts; gear assembly is lubricated by servo coat. On each bogie 4 brake cylinder and brake assembly is mounted. Each cylinder operates 3 brake blocks as such 24 nos. of brake blocks are provided.

Wheels Sanding Arrangement

Rail Guard Cattle Guard

Pipes of Brake System Buffers

Center Buffer coupler Fuel Tank

M.R Tank Axle Generator

Mechanical speedometer sensor Brake system

valves Hand brake chain

Co-Co tri mount bogie is fitted in under truck of WDM2 loco. The short hood side bogie is called front truck and the long hood side bogie is called Rear Truck.

Bogie frame is made of cast steel, on each bogie one center pivot and two side load bearer are provided .The whole load of super structure is divided on these center pivots and side load bearer, each center pivot carries 30% load and side load bearer carries 10% each. On each axle journal, one axle box is fitted. The load is transferred on axle box through helical spring on equalizing beam. There is one set of two equalizing beams, these two beams are tied together by a tie bolt and on each set of the equalizing beam one spring chair is provided on which two sets helical springs are mounted. One set of helical spring having snubber, because of spring and snubber vibration and jerks on the frame are minimized. In this way both bogies having 16 equalizing beams, 16 spring sets and snubber (08 no.).

Traction motor is mounted on each axle with the help of suspension bearing and other end of TM is placed on cross member embarked nose pads. For lubrication of suspension bearing wick pads are provided. Lower end of wick pad is dipped in oil and upper end supplies oil to bearing and axle. On each axle two numbers of suspension bearings are provided, thus total number of suspension bearings is 12.

A 65 teeth drive gear is provided on each axle and a 18 teeth pinion gear fitted on armature of Traction motor is matched with axle gear. This gear assembly is placed in traction motor gear case; it is made up in two parts and fitted together with C-clamp & flange bolts. This gear case is fitted on TM yoke with three foundation bolts; gear assembly is lubricated by servo coat. On each bogie 4 brake cylinder and brake assembly is mounted. Each cylinder operates 3 brake blocks as such 24 nos. of brake blocks are provided.

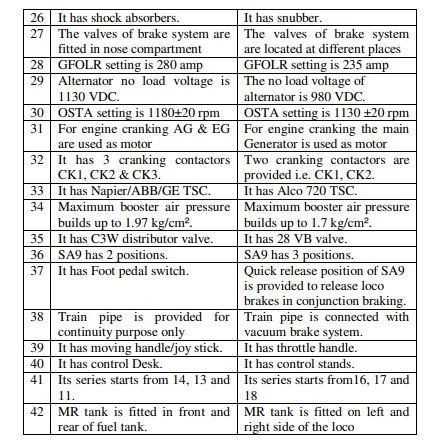

Comparative study of different systems of WDM2 in comparison with WDG-3A loco

Fuel Oil System

Fuel Oil System

- Fuel tank capacity is 5000 lit.

- Marking on glow rod gauge is 540 -5000 liter.

- Glow rod gauge is fitted.

- The tank is welded with superstructure.

- Regulating valve setting is 3.6 kg/cm2 .

- Sump capacity is 990 lit.

- Setting of relief valve is 7.5 kg/cm2 and regulating valve is 4.2 kg/cm2.

- Marking on dip-stick gauge 0- 400 liter.

- After cooler is connected in delivery side of water pump.

- Radiator core is small in size.

- ETS 1,2,3 (Engine Temp. switch) is provided.

- ALCO-720 TSC is provided.

- Maximum BAP is build up to 1.7 kg/cm2 .

- After cooler is small in size.

- Air maze oil bath filter is provided in place of Cyclonic filter.

- Run down test is carried out of TSC.

- Run down test timing is 90 -180 sec.

- Expressor is provided in place of compressor.

- There are six cylinders, out of which three exhauster and other three is compressor cylinder.

- One inters coolers provided.

- NS16 governor is provided.

- Vacuum check valve is fitted for the safety of expressor unit.

- Expressor sump capacity is 30 liters.

- MR1& 2 are provided both side of fuel oil tank.

- 28LAV-1 brake system is fitted; both vacuum and air brake train can be worked.

- In this system SA-9 has three positions.

- Quack release position is used to loco brake in conjunction working.

- 28VBvalve is provided in place of C3W.

- COC with strainer is provided for isolating conjunction braking.

Engine Starting Procedure

Note –

1. In WW governor Loco it is necessary to put On MCB1,2 to ring alarm before pressing Alarm push button located on front panel, otherwise alarm bell will not ring.

2. During Engine starting all indications is similar as WDG-3A Loco except AGFL will glow on closing of MB-1.

- Check and secure the Loco.

- Put ‘ON’ Dome light breaker and switch.

- Close the battery knife switch.

- Put ‘ON’ MB-1 breaker.

- Put ‘ON’ MB-2 breaker

- Put ‘ON’ MFPB-1 breaker.

- Put ‘ON’ MFPB-2 breaker.

- Put ‘ON’ CEB breaker.

- Put ‘ON’ FPB breaker

- Kept ECS from Idle to run position three times and kept in Idle at last. Alarm will ring in run position, on hearing it the staff working on locomotive will alert and come to know that engine is starting.

- Press the Start Button

- CK1 and CK2 will pick up and engine will crank.

- When lube oil pressure builds up to 1.6 kg/cm2 then ESLP will extinguish.

- Release start button and ensure dropping of CK1 & CK2.

- Put ON AGFB on front panel.

Note –

1. In WW governor Loco it is necessary to put On MCB1,2 to ring alarm before pressing Alarm push button located on front panel, otherwise alarm bell will not ring.

2. During Engine starting all indications is similar as WDG-3A Loco except AGFL will glow on closing of MB-1.

Engine Stopping Procedure – Same as WDG-3A Loco.

Engine Speed Control

The engine speed is control same as WDG-3A Loco, interlocks of GFOLR and VAPR is not provided in speed control circuit. 8th notch speed is 1000 rpm.

GFC Control

Circuit It is same as in WDG-3A Loco, NCI of GFOLR, VAPR is not provided and CK1, CK2 (NCI) is replacement of CK3 (NCI).

Transition

1. Three transitions are takes place in WDM-2 loco at the speed of 30, 50, 80 km/h respectively. (SP to SP+FS, SP+FS to P and P to P+FS )

2. FSR, FSRR, FS contactors are provided on this Loco.

3. Four cards (210/1, 210/2,210/3,207) are provided on TRP. Indication Lamps Following, indication lamps are provided on both control stands in WDM2 Loco.

Engine Speed Control

The engine speed is control same as WDG-3A Loco, interlocks of GFOLR and VAPR is not provided in speed control circuit. 8th notch speed is 1000 rpm.

GFC Control

Circuit It is same as in WDG-3A Loco, NCI of GFOLR, VAPR is not provided and CK1, CK2 (NCI) is replacement of CK3 (NCI).

Transition

1. Three transitions are takes place in WDM-2 loco at the speed of 30, 50, 80 km/h respectively. (SP to SP+FS, SP+FS to P and P to P+FS )

2. FSR, FSRR, FS contactors are provided on this Loco.

3. Four cards (210/1, 210/2,210/3,207) are provided on TRP. Indication Lamps Following, indication lamps are provided on both control stands in WDM2 Loco.

Safety Devices

Safety Fittings

- OPS

- LWS

- OSTA

- SAR

- DMR

- GR

- WSR

- ETS3

- Circuit breakers

Safety Fittings

- Head light (with proper focus)

- Flasher light

- Marker light (with red glass)

- Rail Guard

- Cattle Guard

- Foundation bolts of Buffer.

- CBC locking pin

- Horns

- Wiper

- Sanders (with pipe fitment)

- Speedometer (with speed recorder)

- Equalizing beam tie bolts and its split cutter.

- Equalizing beam safety bracket.

- Brake blocks hanger pins and its retaining bolts.

- ‘J’ bracket of brake pull rod.

- Safety chain of brake cross tie bar

- Axle box stay plate and its bolts.

- Traction motor gear case foundation bolts

- Traction motor Gear case ‘C’ clamp and its flange bolts.

- Suspension bearing housing bolts.

- Traction motor nose suspension guide bolts.

- Bogie safety pin.

- Hand brake.

Oil Checking Points in WDM-2 loco

1. Fuel oil tank capacity is 5000 litter and both side fuel oil glow rod is provided having marking from 540 to 5000 liter. Average of both side glow rod oil level to be noted, if oil level is less than 540 liter shut down the engine.

2. Each axle having two suspension bearing, each bearing has oil cap and it is to be ensured that oil is available in the cap.

3. Each traction motor gear case having filling cap which should be tied with nut and bolt.

4. Each bogie has two side load bearer with oil cup and it is to be ensured that oil is available in each cup.

5. Each bogie has one center pivot with oil cup and it is to be ensured that oil is available in each cup.

6. Dipstick gauge is provided on engine right side in generator room to check the generator gear case oil level; it should be above minimum mark.

7. EH governor has two spy glasses, bottom one should be full and top one should be more than half. WW governor has glass tube to check oil level it should be above marking provided on the tube.

8. A dipstick gauge is provided to check oil level of engine lube oil sump. It has marking from 0 to 400 liter. To check oil level engine should be on idle and CCM is in running.

9. Spy glass and dipstick gauge are provided in expresser, dipstick having 5 marking oil should be above three marks. Engine should be shut down before checking the oil level while checking with dipstick gauge.

10. Spy glass is provided on air maize oil bath filter having two marking; add and full. Oil level should be above Add mark.