GENERAL DATA OF WDG-3A LOCOMOTIVE

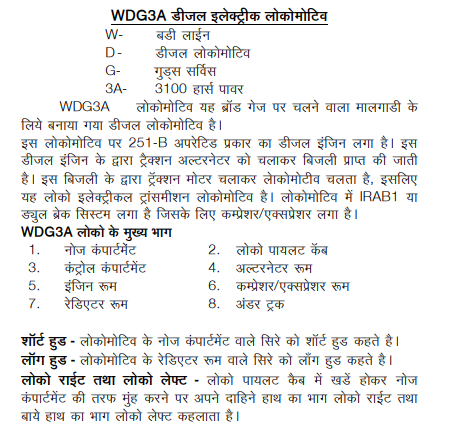

WDG3A Diesel Electric locomotive

W – Broad gauge

D - Diesel Engine

G – Goods Service

3A –Engine Horse Power -3100 HP

This loco is having up rated Diesel engine fitted with fuel efficient kit, Napier or GE make TSC, incorporated IRAB1 and facilitated with AC – DC transmission.

Main compartments of WDG3A Loco from short hood to long hood

1. Nose compartment

2. Loco Pilot cab

3. Control compartment

4. Alternator Room

5. Engine Room

6. Compressor Room

7. Radiator Room

8. Under truck

Short hood - Nose compartment end is called short hood.

Long hood - Radiator room end is called long hood.

Loco Right and Loco left - In loco pilot cab when you stand and facing towards nose compartment, your right hand side is loco right and your left hand side is loco left.

Engine right and engine left - In loco pilot cab when you stand and facing towards engine room, your right hand side is engine right and your left hand side is engine left.

Power take off end - In engine room alternator end is called power take off end.

Free end - In engine room compressor end is called free end.

Note-

1. Counting of parts of Alternator room, Engine room and compressor room as per Engine left and Engine right.

2. Counting of parts of Locomotive parts from short hood to long hood.

3. counting of parts of Engine from free end to power take off end.

Different major parts in compartments

1. Nose Compartment

Dynamic Braking Blower motor ( BKBL) Dynamic braking Grids

NS-1 Reducing valve and its COC Battery knife switch (BS)

Control Reservoir with drain cock Horn and wiper COC

a. On brake panel

MU2B valve, 3/4” COC, C3W distributor valve, F1 selector valve, C2 relay valve, Addl. C2 relay valve, N1 limit valve, D24B valve, 24AD check valve, EPG pressure switch, EPG COC, MR pressure gauge, Power cut off pressure switch, Air flow measuring valve, 1¼” COC, Duplex valve, EPG toggle switch, 110 cubic inch reservoir. On outer wall of Nose compartment head light, flasher light marker light and multiple unit jumper couples are provides.

2. Loco Pilot Cab

a. On both control Desk

A-9 valve with COC SA- 9 valve with COC

Master Handle (MH) Selector Handle (SH)

Reverser Handle (RH) Load meter

Brake pipe Pressure Gauge Air flow indicator

MR pressure Gauge BC pressure gauge

Lighting switches Speedometer

Head light switch (HLS) PATB

Flasher light control box Foot paddle switch

Multiple unit shut down switch (MUSD) Sander push button

Master Fuel pump Breaker (MFPB) Main control breaker MCB

Generator Field cut out switch (GFCO) Indication Lamp panel

Horn push button

Other than above Loco Pilot Cab has Emergency flap valve, Hand Brake, Wiper servo motor, Dom light.

b. On front panel wall

Cab light circuit breaker Head light circuit breaker

Engine room light circuit breaker Dom light circuit breaker

Cyclone motor circuit breaker MB-1

MB-2 FPB

AGFB CEB

Alarm push button ECS

GR1 GR2

Alarm gong MCO

Indication panel Start button

Stop button GFOLR reset button

3. Control Compartment

4. Alternator Room

Traction Alternator, Auxiliary Generator,

Exciter Generator, FTTM,

Generator Gear Case and its dip stick gauge, rectifier panel.

5. Engine Room

251-B up rated with fuel efficient kit type diesel engine

Fuel injection pump, High Pressure Line, Water Jumper pipe, Water riser pipe, Inlet elbow, Exhaust elbow, Exhaust manifold, Cross over pipe

On engine right side

Engine Governor, Tacho Generator, Lube oil Dipstick gauge Crankcase Explosion Door , Primary filter, Secondary filter, OSTA Fuel oil Relief valve, Bubble collector, Lube secondary Header, Centrifugal filter, Right side fuel oil gallery

On engine left hand side

Crank case Exhauster Motor& Blower, Fuel oil Regulating valve Lube oil strainer, Bubble collector, Lube oil Main Header Lube secondary Header, Left side fuel oil gallery

On free end

Turbo super charger, After cooler, Water pump ,Lube oil pump

6. Compressor Room

Compressor unit, Cyclonic filter, Fuel pump motor(Fuel pump, Gov. pump), Water drain cock, Car body filter, ETS-1, 2, 3.

Water temperature gauge, LWS& its Test cock, Lube oil relief valve Lube oil regulating valve, EPG’s EP valve and its COC with dirt collector

7. Radiator Room

Lube oil filter drum and its drain cocks Lube oil by pass valve Lube oil cooler Radiator core Radiator fan Rear Truck Traction Motor Blower (RTTM) Expansion tank no. 1&2 Right Angle Gear Box Eddy current clutch coil (ECC) On outer wall of radiator Room Head light flasher light, water level gauge, marker light and multiple unit jumpers are provided.

8. Under Truck

CO-CO high adhesion bogie Front truck

Rear Truck Center Pivot

Side load Bearer Helical Spring

Vertical Shock absorber(08) Horizontal shock absorber (04)

Equalizing beam Axle Box

Compensating beam D shackle (08)

Axle Journal Traction motor

Nose pad Pinion Gear

Axle Gear Traction Motor Gear case

Brake cylinder Brake assembly

Wheels Sanding Arrangement

Rail Guard Cattle Guard

Pipes of Brake System Buffers

Center Buffer coupler Fuel Tank

MR Tank Axle Generator

Mechanical speedometer sensor Hand brake chain

Bogie COC

Front Truck Traction Motor Blower (FTTM)

Location – Alternator room Function – To cool Traction motor no 1, 2 and 3 by air, its shaft having 43 teeth gear which is driven by Main Alternator bull gear. Incase of abnormal sound from FTTM, fail the loco.

Rear Truck Traction Motor Blower (RTTM)

Location- Radiator room Function - To cool Traction motor no 4, 5, and 6 by air. It shaft is having a pulley which has 6 “v” belts, these belts are driven by a pulley on extension shaft No. 2 Minimum 4 belts are required. Engine must be shutdown to check the belts and its tension. If the number of belts is less then 4, fail the loco.