MODERN COACHES

4.1 DEMU COACHES

The special features of High Horse Power DEMU coach; These coaches are fitted with Air springs in the secondary suspension to maintain a constant buffer height irrespective of loaded condition to give comfortable riding to the passengers.

Bottom bolsters, Stirrup links and Equalizing stays are eliminated. It is provided with an emergency spring inside the air spring to support the bolster in case air spring fails. Schaku couplers are provided and Side buffers are eliminated.

4.2 Air Spring

Air spring is a rubber bellow containing pressurized compressed air with an emergency rubber spring providing various suspension characteristics to maintain a constant Buffer height irrespective of the loaded condition.

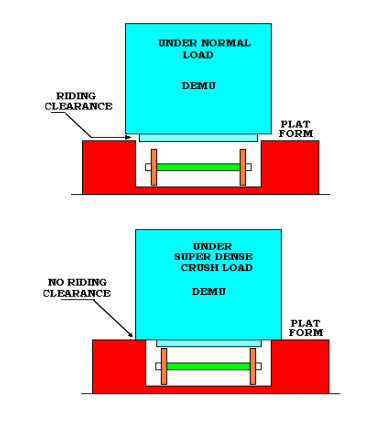

In suburban trains like DEMU, the number of passengers entraining (Super Dense Crush Load) in to

the coach cannot be controlled and hence the payload of the coach increases from 18 tons to 34 tons. This abnormal increase of payload reduces the Riding Clearances between the Coaches and Wayside platforms and also reduces buffer height resulting in severe hitting of coach on the plat forms.

Due to the Super Dense Crush Load the bolster springs become solid, which in turn damages / breaks the Coil springs resulting in discomfort to the passengers. To overcome the above problems an Air Suspension (Air spring) is introduced in the secondary suspension to maintain a constant buffer height irrespective of loaded conditions by varying the pressure of air inside the air spring.

Components of Air Suspension

Air spring Emergency spring

Leveling valve Installation lever with adjusting Screw rod

Duplex check valve Main Air Reservoir

Auxiliary Reservoir Isolating cock

Leveling valve: The leveling valve is fitted with Top bolster and is designed to move up and down along with bolster. Under normal condition, it is designed to take LAP position when the actual buffer height is equal to the required buffer height.

The function of leveling valve is to connect the main reservoir with the air spring to admit more air in to the Air spring, whenever the actual buffer height is less than the required buffer height due to abnormal increase in the Pay load (Super Dense Crush load).

It also connects the air springs with exhaust to release the excess air from air spring, whenever the actual buffer height is more than required buffer height due to reduction in the Pay load after detraining of passengers from the coach

Installation lever: It is fitted between the levelling valve and bottom of the bogie frame. The function of installation lever is to operate the levelling valve automatically by moving the handle of the levelling valve up and down according to the condition of the load. The up and down movement of handle of levelling valve admits the compressed air in to the Air spring or releases the compressed air from the air spring through levelling valve in proportion to the pay load of the coach.

Duplex Valve: It is a double check valve provided between the two Air springs of the same bogie. It operates with a Pressure differential of 1.5 bar. Basically it comprises of two check valves side by side, arranged so that air can flow in either direction whenever the air pressure differential exceeds the pre-set value of 1.5 bar. Whenever a burst of air spring occurs on one side, this valve will ensure that no severe tilt or twist occurs during movement of the coach.

Both the check valves of Duplex valve remains closed, if the pressure between the two springs is within 1.5 bars. When the differential air pressure exceeds the preset value, the air at higher pressure overcomes the spring pressure and flows to the lower pressure via the check valve. The flow continues till the differential reaches the preset value.

In case of burst of Air Spring, the air leaks to atmosphere. Due to high-pressure differential, the Duplex check valve releases the air from the intact air spring through burst air spring. Thus 158 complete coach will gradually come down and rest on the emergency rubber springs.

Auxiliary reservoir of Air Spring:

It isfitted with the Air spring. The capacity of this reservoir is 20 Ltrs. There is an orifice kept between air spring and additional reservoir. It acts as an Air damper to overcome vertical and lateral oscillations so as to increase the riding comfort.

Main Air reservoir:

The capacity of the main reservoir is 150 ltrs and it is exclusively used for feeding the compressed air in to the Air Spring.

Emergency Springs:

The function of emergency spring is to support the top bolster to prevent tilt of coaches whenever the Air spring burst.

4.2.1 Comparison of Helical coil springs with Air Springs:

Unlike steel springs, air springs retain their height under changing loads. The low natural frequency of air spring suspension remains virtually constant. In case of coil spring, deflection is proportionate to the load. Therefore under high payload situation, space constraint becomes critical, leading to the use of stiffer springs resulting in unsatisfactory ride behaviour and reduced speed potential. Air springs through their control mechanism offer a load proportionate stiffness, constant floor height and better ride behaviour with higher speed.

Advantages of Air Suspensions

Capable to sustain Super Dense Crush Load of suburban traffic at high speeds. It maintains a Constant floor height of coach. It facilitates excellent riding comfort with riding index of 2.5. Safe running due to the excellent Air Damping. Low design height. Unusual noise emitted due to hitting of coaches on the plat forms is eliminated. The Stirrup links, Coil springs and equalizing stays are eliminated and therefore easy to maintenance.